Product Description:

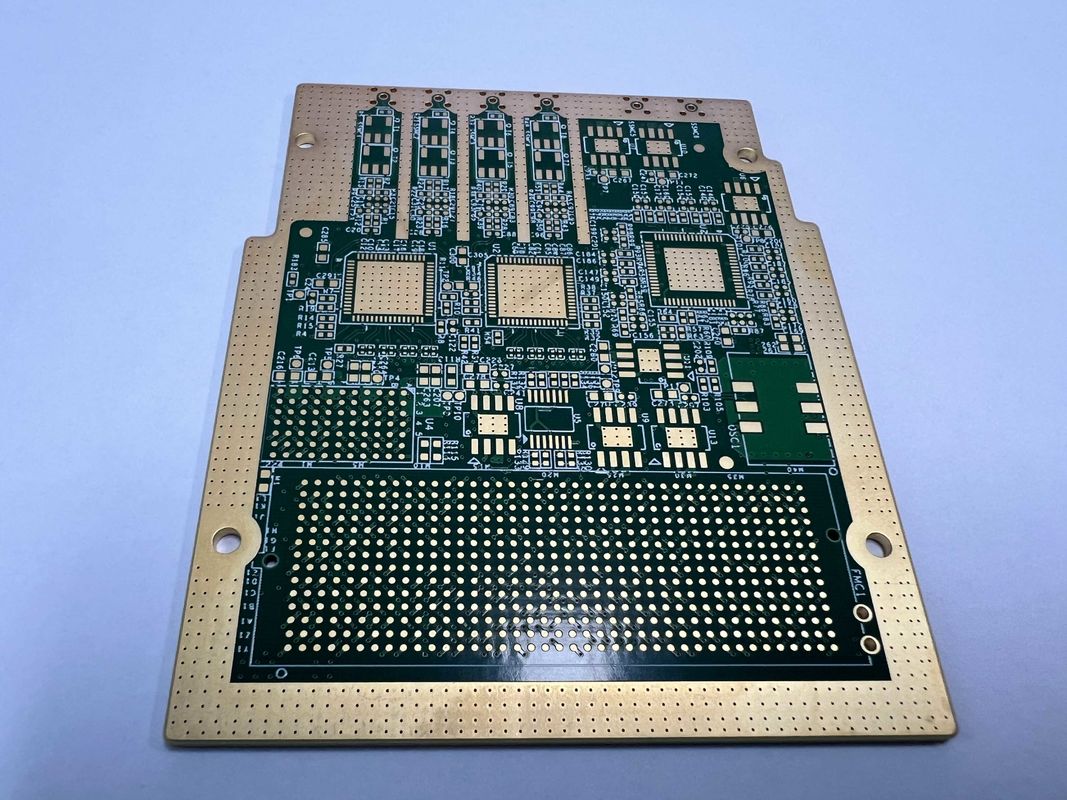

A High Speed PCB Board refers to a type of circuit board that is specifically designed for high-frequency and high-speed applications. These boards are crucial in accommodating the increasing demands for faster data transmission and signal integrity in various electronic devices and systems. One of the key players in the production of High Speed PCB Boards is the HDI PCB Manufacturing process, which stands for High-Density Interconnect Printed Circuit Board.

One notable offering in the realm of HDI PCBs is the HDI PCB Board with the following specifications:

-

VIP Process: Yes

-

Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

-

Finished Copper Thickness: 1oz

-

Min. Solder Mask Bridge: 0.075mm

-

Silkscreen: White, Black, Yellow, etc.

The inclusion of the VIP Process in this HDI PCB Board product signifies a premium level of manufacturing and quality assurance in its production. This process ensures that the board meets the highest standards of performance and reliability, making it a top choice for applications that demand superior speed and precision.

Utilizing Glass Epoxy material from Rogers Corp., specifically the RO4350B with a Tg of 280℃ and Er<3.48, enhances the board's thermal stability, signal integrity, and overall electrical performance. This choice of material is crucial in maintaining the integrity of high-frequency signals and reducing signal loss, making it an ideal option for high-speed applications.

The Finished Copper Thickness of 1oz on this HDI PCB Board further enhances its conductivity and ensures efficient signal transmission across the board. This attribute is particularly important in high-speed applications where signal integrity and reliability are paramount.

With a Min. Solder Mask Bridge of 0.075mm, this HDI PCB Board offers precise spacing between components and solder points, reducing the risk of short circuits and ensuring consistent performance under high-frequency conditions. This level of precision is essential in maintaining signal integrity and preventing signal interference in complex electronic systems.

Additionally, the availability of multiple Silkscreen color options such as White, Black, Yellow, etc., provides customization flexibility for users to label and identify components on the board easily. This feature not only adds to the aesthetics of the board but also aids in efficient assembly and troubleshooting processes.

In conclusion, the HDI PCB Board with VIP Process, Glass Epoxy RO4350B, 1oz Copper Thickness, 0.075mm Min. Solder Mask Bridge, and various Silkscreen options offers a high-quality solution for demanding high-speed applications. Its superior performance characteristics make it an ideal choice for industries where reliability, precision, and speed are of utmost importance.

Features:

-

Product Name: HDI PCB Board

-

Feature: Immersion Silver

-

Finished Copper Thickness: 1oz

-

Key Words: High Density Interconnector, High Density PCB, HDI Printed Circuit Boards, DDR4 PCB

-

Silkscreen: White, Black, Yellow, Etc.

-

Copper Thickness: 0.5oz-6oz

Technical Parameters:

|

Vias Aspect Ratio

|

16:1

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Copper Thickness

|

0.5oz-6oz

|

|

Aspect Ratio

|

10:1

|

|

Vip Process

|

Yes

|

|

Thickness

|

1.6mm, ±10%

|

|

Min. Solder Mask Bridge

|

0.075mm

|

|

Surface Mount Technology

|

Available

|

|

Pcb Assembly Process

|

SMT THT DIP SMT PCB Assembly

|

|

Feature

|

Immersion Silver

|

Applications:

High Density PCB (HDI) boards are advanced circuit boards designed for high-density model applications. With various surface finish options such as HASL, ENIG, OSP, Immersion Silver, and Immersion Tin, these boards are versatile and suitable for a wide range of scenarios.

The HDI PCB boards with white, black, or yellow silkscreen options offer flexibility in design and customization, making them ideal for applications where specific color coding or branding is required.

Featuring a finished copper thickness of 1oz, these boards provide excellent conductivity and signal integrity, making them perfect for high-density model board applications such as HD SDI converters.

Constructed with glass epoxy material RO4350B Tg280℃, Er<3.48 from Rogers Corp., these boards offer high thermal performance and low dielectric constant, ensuring reliable operation even in demanding environments.

Thanks to the VIP process implemented in the manufacturing of these boards, they exhibit superior quality and precision, meeting the stringent requirements of high-density applications.

With their high-density design, advanced surface finish options, customizable silkscreen colors, optimal copper thickness, and reliable glass epoxy material, HDI PCB boards are the perfect choice for a wide range of scenarios requiring high-performance circuit boards, such as HD SDI converters, high-density model boards, and other advanced electronics applications.

Customization:

Enhance your HDI PCB Manufacturing with our Product Customization Services tailored for your specific needs:

Vias Aspect Ratio: 16:1

VIP Process: Yes

PCB Assembly Process: SMT, THT, DIP, SMT PCB Assembly

Finished Copper Thickness: 1oz

Feature: Immersion Silver

Experience top-notch customization for your DDR4 PCB, HD SDI Converter, and more!

Support and Services:

The HDI PCB Board product comes with comprehensive Product Technical Support and Services to ensure optimal performance and customer satisfaction. Our experienced technical support team is available to assist with any product-related inquiries, troubleshooting, and guidance on best practices. In addition, we offer services such as product training, customization options, and regular product updates to meet the diverse needs of our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!