Product Description:

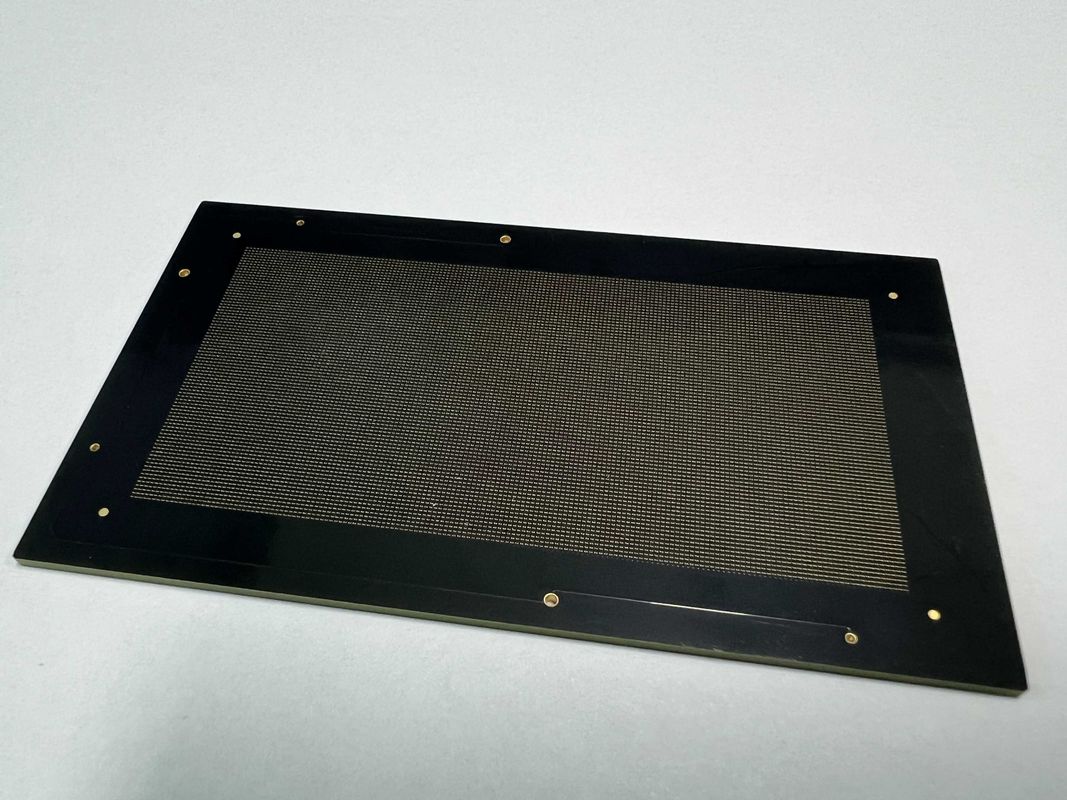

The High Density Interconnector (HDI) PCB Board is a cutting-edge product designed for high-speed applications, ensuring superior performance and reliability. Equipped with advanced features such as RO4350B glass epoxy material, with a high glass transition temperature of 280℃ and a low dielectric constant of less than 3.48 from Rogers Corp., this PCB board offers exceptional thermal stability and signal integrity.

One of the key highlights of this HDI PCB board is its impressive vias aspect ratio of 16:1, which allows for the efficient routing of high-density interconnects without compromising signal quality. This feature is essential for demanding applications such as HD SDI converters, where signal integrity is paramount.

In addition to its high-performance materials and design, this HDI PCB board also offers versatility in terms of silkscreen options. With choices including white, black, yellow, and more, users can customize the board to suit their specific branding or functional requirements.

Furthermore, the HDI PCB board is equipped with mini holes as small as 0.1mm, enabling precise and compact designs that are ideal for space-constrained applications. Whether used in HD SDI converters or other high-speed PCB applications, these mini holes contribute to the overall efficiency and reliability of the board.

Overall, the High Density Interconnector (HDI) PCB Board stands out as a top-of-the-line product that meets the stringent demands of modern high-speed electronics. With its advanced materials, high vias aspect ratio, versatile silkscreen options, and mini holes for compact designs, this HDI PCB board is the ideal choice for applications such as HD SDI converters, ensuring optimal performance and durability in every use case.

Features:

-

Product Name: HDI PCB Board

-

Feature: Immersion Silver

-

Silkscreen: White, Black, Yellow, Etc.

-

Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

-

Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

-

Key Words: High Density Interconnector

Technical Parameters:

|

Vip Process

|

Yes

|

|

Feature

|

Immersion Silver

|

|

Vias Aspect Ratio

|

16:1

|

|

Surface Mount Technology

|

Available

|

|

Finished Copper Thickness

|

1oz

|

|

Mini Holes

|

0.1mm

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Min. Solder Mask Bridge

|

0.075mm

|

|

Copper Thickness

|

0.5oz-6oz

|

|

Thickness

|

1.6mm, ±10%

|

Applications:

One of the key attributes of the HDI PCB is its impressive vias aspect ratio of 16:1, allowing for dense routing and interconnections in a compact space. This feature makes the HDI PCB perfect for applications that require intricate circuit designs and high interconnect density, such as smartphones, tablets, and wearable devices.

The use of glass epoxy material, specifically RO4350B from Rogers Corp., with a high Tg of 280℃ and a low dielectric constant (Er<3.48), ensures excellent thermal stability and signal integrity in the HDI PCB. This makes it suitable for demanding environments where temperature fluctuations and signal interference are common.

With a finished copper thickness of 1oz, the HDI PCB provides optimal conductivity and signal transmission capabilities, making it suitable for high-frequency applications such as telecommunications equipment, medical devices, and aerospace systems.

Furthermore, the HDI PCB supports surface mount technology, offering enhanced flexibility in component placement and assembly processes. This feature makes the HDI PCB versatile and adaptable to a wide range of product designs and manufacturing requirements.

In summary, the HDI PCB is a high-density model board that excels in demanding applications that require intricate circuit designs, high interconnect density, superior signal integrity, and reliable performance. Its advanced features and exceptional quality make it a top choice for engineers and designers looking to push the boundaries of electronic innovation.

Customization:

Product Customization Services for HDI PCB Manufacturing

Aspect Ratio: 10:1

PCB Assembly Process: SMT THT DIP SMT PCB Assembly

Silkscreen: White, Black, Yellow, Etc.

Copper Thickness: 0.5oz-6oz

Surface Mount Technology: Available

Support and Services:

The Product Technical Support and Services for the HDI PCB Board product include:

- Comprehensive technical support for installation, troubleshooting, and maintenance.

- Assistance with product customization and integration into existing systems.

- Access to online resources such as user manuals, FAQs, and troubleshooting guides.

- Regular software updates and bug fixes to ensure optimal performance.

- Training sessions and workshops for users to maximize the potential of the product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!