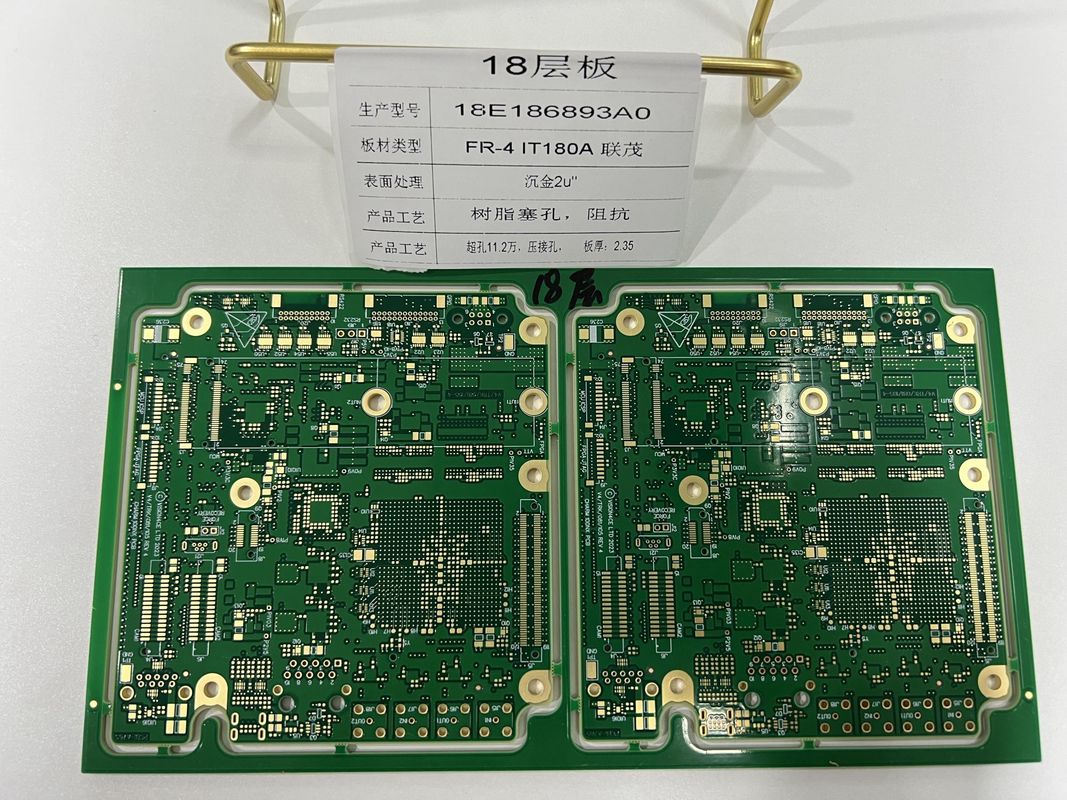

Product Description:

The 4L 1+N+1 HDI Boards are specially designed to cater to the needs of electronic engineers, researchers, and hobbyists who are looking for a High Density Model Board that can be used in a wide range of applications. The board's Impedance Control feature ensures that the electrical signals transmitted through the board are stable and consistent, while the Lamp Socket feature enables the board to support high-power lighting applications.

The Min Trace of 3/3Mil is another standout feature of the 4L 1+N+1 HDI Boards. This feature enables the board to support high-density circuit designs, making it ideal for applications that require a High Density Model Board. Additionally, the board's Aspect Ratio of 10:1 means that it can be used in applications that require a high level of design flexibility.

Overall, the 4L 1+N+1 HDI Boards are a high-quality, reliable, and efficient solution for those who require a High Density PCB for their electronic applications. With its impressive feature set, this board is sure to meet the needs of even the most demanding applications. So if you're looking for a High Density Model Board that can offer you the performance and reliability you need, the 4L 1+N+1 HDI Boards are definitely worth considering.

Features:

- Product Name: HDI PCB Board

- Special Request: Half Hole, 0.25mm BGA

- Impedance Control: Yes

- Testing: 100%E-Testing,X-RAY

- Board Layer: 6-32L

- Board Thickness: 0.2mm-6.00 Mm(8mil-126mil)

- Type: HDI PCB

- Usage: High Speed PCB Board, DDR4 PCB

Technical Parameters:

| Product Name: |

4L 1+N+1 HDI Boards |

| Layer Count: |

4-20 Layers |

| Testing: |

100%E-Testing,X-RAY |

| Special Request: |

Half Hole, 0.25mm BGA |

| Raw Material: |

FR4 IT180 |

| Thickness: |

0.4-3.2mm |

| Hole Size: |

0.1mm Laser Drill |

| Board Thickness: |

0.2mm-6.00 Mm(8mil-126mil) |

| Minimum Hole Size: |

0.15mm |

| Key Words: |

High Density Interconnector, HDI PCB Board, High Density PCB, HD SDI Converter |

Applications:

One of the key features of HDI PCB Board is its testing capabilities. With 100% E-testing and X-ray, the HDI PCB Board ensures that all components and connections are working correctly, providing reliable and accurate results. This makes it a perfect choice for mission-critical applications such as aerospace, defense, and medical equipment.

Another important attribute of HDI PCB Board is its aspect ratio, which is typically 10:1. This allows for a higher density of components to be placed on the board, resulting in a smaller form factor. This makes it a great option for handheld devices, wearables, and IoT devices where size is a priority.

The number of layers on an HDI PCB Board can range from 6 to 32 layers, which provides design flexibility and allows for complex, high-density designs. This makes it suitable for a broad range of applications such as automotive, consumer electronics, and telecommunications.

The raw material used in HDI PCB Board is FR4 IT180, which is a high-performance laminate material. It offers excellent thermal stability, low dielectric loss, and high mechanical strength. These properties make it a great choice for applications that require high-speed signal integrity, such as telecommunications and computing.

The hole size on an HDI PCB Board is typically 0.1mm Laser Drill. This allows for a greater number of components to be placed in a smaller space, resulting in a higher density design. This makes it a great option for applications such as computing, telecommunications, and industrial control systems.

In summary, HDI Printed Circuit Boards are the perfect solution for applications that require high-density, complex designs. With its testing capabilities, aspect ratio, board layer, raw material, and hole size, HDI PCB Board is a versatile option for a variety of applications, including aerospace, defense, medical equipment, automotive, consumer electronics, telecommunications, and computing.

Customization:

Our High-Speed PCB product, HDI PCB Board, is customizable to fit your specific needs. We offer customization for board thickness, ranging from 0.2mm-6.00mm (8mil-126mil) and hole size with 0.1mm laser drill. Our HDI PCB Board has an aspect ratio of 10:1, making it perfect for high-speed PCB applications such as HD SDI Converter. The raw material used for our HDI PCB Board is FR4 IT180, ensuring durability and reliability. We also offer customization for layer count, ranging from 4-20 layers. Contact us to learn more about our product customization services for HDI PCB Board.

Support and Services:

Our HDI PCB Board product comes with comprehensive technical support and services to ensure that our customers get the most out of their purchase. Our team of experienced engineers is available to assist with any technical questions or issues that may arise during installation or operation. We also offer customization services to meet specific customer requirements and provide design consultation to ensure optimal performance and functionality. Additionally, we offer warranty and repair services to ensure that any defects or issues with the product are promptly addressed and resolved.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!