Product Description:

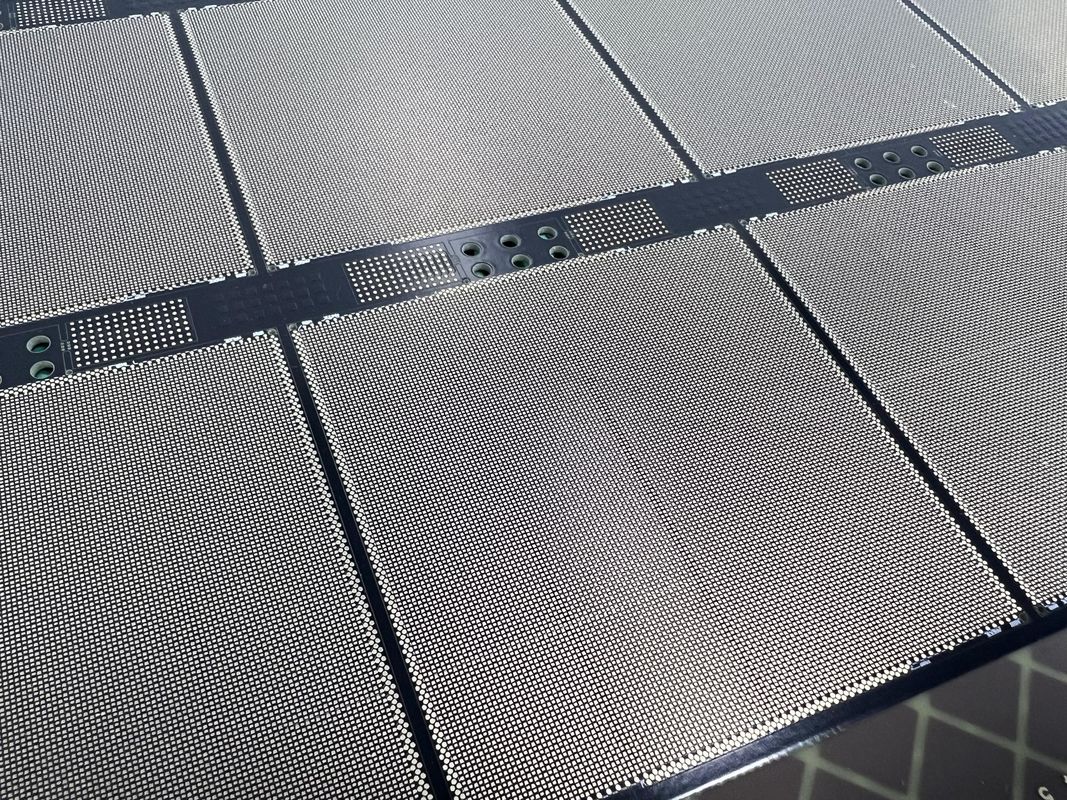

Our HDI PCB board boasts an impressive minimum trace width of 3/3mil, ensuring that your circuits and connections are precise and efficient. Additionally, our board features an aspect ratio of 10:1, which allows for even more complex and intricate designs.

Our high-speed PCB board is capable of handling even the most demanding applications, including DDR4 PCB technology. Whether you need a board for telecommunications, computing, or industrial applications, our HDI PCB board is up to the task.

One of the unique features of our HDI PCB board is its ability to accommodate lamp sockets, making it an ideal choice for lighting applications. This special requirement allows for easy and convenient installation of lamp components, making it a popular choice for designers and engineers in the lighting industry.

Our HDI PCB board is available in a range of thicknesses, from 0.4mm to 3.2mm, ensuring that you can find the perfect board for your specific needs. Whether you need a thin and flexible board for a compact device or a thick and sturdy board for an industrial application, we have you covered.

Overall, our HDI PCB board is a top-of-the-line product that is perfect for any application that requires high-speed and reliable PCB technology. With its durable and high-quality construction, it is sure to meet and exceed your expectations.

Features:

- Product Name: HDI PCB Board

- Pcb Name: 4L 1+N+1 HDI Boards

- Minimum Hole Size: 0.15mm

- Board Layer: 6-32L

- Min Trace: 3/3Mil

- Aspect Ratio: 10:1

- High Density Model Board

- High Speed PCB

- DDR4 PCB

Technical Parameters:

| Technical Parameters |

Specifications |

| Product Name |

High Density Model Board / HDI PCB Board |

| Board Layer |

6-32L |

| Board Thickness |

0.2mm-6.00 Mm(8mil-126mil) |

| Layer Count |

4-20 Layers |

| Min Hole Size |

0.15mm |

| Hole Size |

0.1mm Laser Drill |

| Impedance Control |

Yes |

| Min Trace |

3/3Mil |

| Thickness |

0.4-3.2mm |

| Special Requirements |

Lamp Socket |

| Key Words |

High Density Interconnector, HDI PCB Board, High Speed PCB |

Applications:

- Layer Count: 4-20 Layers

- Board Layer: 6-32L

- Aspect Ratio: 10:1

- Impedance Control: Yes

- Thickness: 0.4-3.2mm

1. Consumer Electronics: HDI PCBs are widely used in consumer electronics, such as smartphones, tablets, laptops, and smartwatches. These devices require high-density interconnects and fine-pitch components, which can be achieved through HDI PCBs. The small size and thinness of HDI PCBs make them ideal for use in portable devices.

2. Medical Devices: HDI PCBs are also used in medical devices such as ultrasound machines, MRI machines, and blood glucose monitors. These devices require high reliability and performance, and HDI PCBs can provide the necessary wiring density and reduced signal loss to ensure accurate data transmission.

3. Aerospace and Defense: HDI PCBs are used in the aerospace and defense industry for their high reliability and performance. These PCBs are used in avionics systems, satellites, and missile guidance systems, where high-density interconnects and signal integrity are essential.

4. Automotive Industry: The automotive industry uses HDI PCBs in a wide range of applications, such as advanced driver-assistance systems, infotainment systems, and GPS navigation systems. These applications require high performance and reliability, and HDI PCBs can provide the necessary wiring density and signal integrity.

In conclusion, the HDI PCB Board product is suitable for a wide range of applications that require high-performance and high-reliability, such as consumer electronics, medical devices, aerospace and defense, and the automotive industry. Its attributes, including layer count, board layer, aspect ratio, impedance control, and thickness, make it an ideal solution for these applications.

Customization:

Our High Density Model Board product offers customizable options to meet your specific needs. With layer counts ranging from 4-20, you can choose the perfect amount of layers for your project. Our 4L 1+N+1 HDI Boards are perfect for high density interconnector (HDI) PCB manufacturing.

The thickness of our boards can be customized between 0.4-3.2mm, and the board layer options range from 6-32L. Our High Density Model Board is designed to meet the highest industry standards, ensuring top-quality performance for your project.

Trust us to provide the best High Density Model Board options for your HDI PCB manufacturing needs.

Support and Services:

Our HDI PCB Board product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. Our team of experienced engineers and technicians are available to assist with any technical inquiries or issues that may arise during the design, production, and testing phases.

We offer a range of services to support our HDI PCB Board product, including:

- Design consultation and review

- Prototype assembly and testing

- Volume production and testing

- Failure analysis and troubleshooting

- Repair and refurbishment

- Product customization

Our commitment to quality and customer satisfaction is evident in our rigorous testing and inspection processes, as well as our adherence to industry standards and regulations. We strive to provide timely, efficient, and effective technical support and services to ensure the success of our customers' projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!