Product Description:

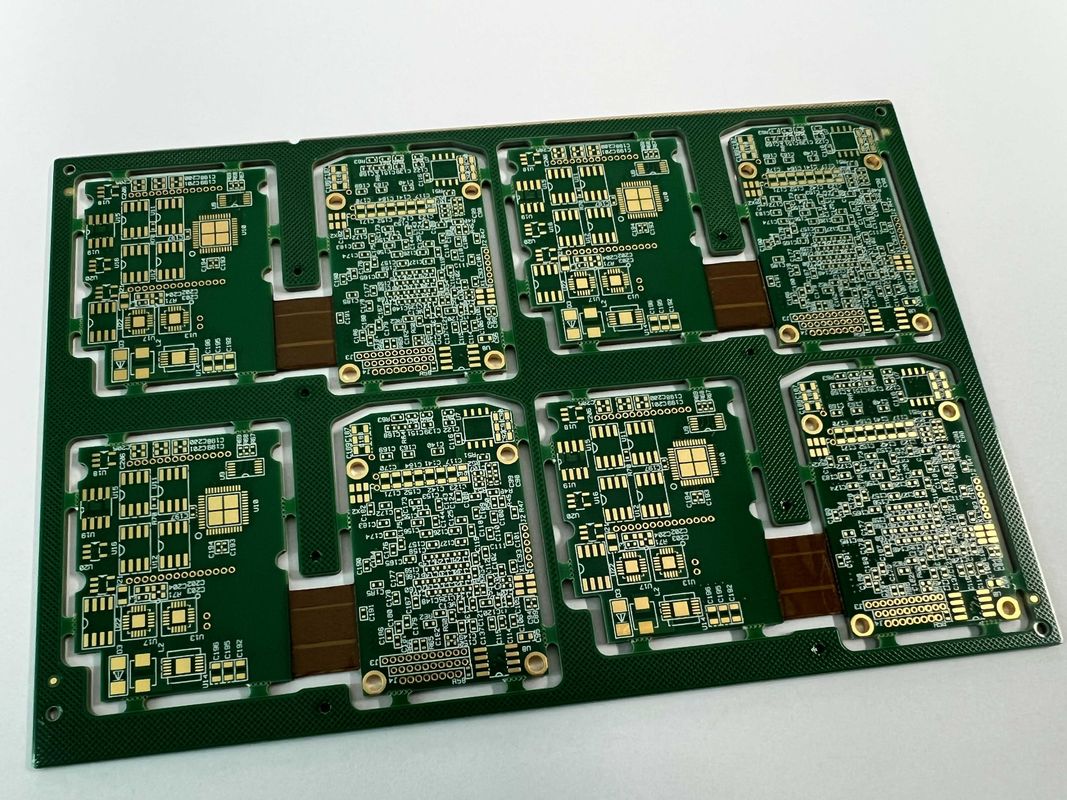

The Rigid Flex PCB is a high-tech solution that integrates the best attributes of both flexible printed circuit boards and rigid printed circuit boards. This product, with its 4 Layer construction, exemplifies advanced engineering in the field of electronic interconnects. It offers a seamless blend of flexibility and stability, making it ideal for dynamic applications where space and weight are significant constraints. With the capability to vary the PCB layers from 1 to 28 layers, the Rigid Flex PCB caters to a wide range of complexities and functionalities, making it a versatile choice for various industries.

One of the key features of this Rigid Flex PCB is its surface finishing. The HASL LF (Hot Air Solder Leveling, Lead-Free) finish ensures that the product is not only reliable but also environmentally friendly. This type of finishing provides a robust surface for soldering while minimizing the impact on the environment by avoiding the use of lead, which is harmful to both human health and the ecological system.

The Rigid Flex PCBs are designed with a bend radius ranging from 0.5 to 10mm. This feature is crucial for the 2. Bendable Rigid-Flex PCB application, as it allows the PCB to be bent or folded without compromising the integrity of the electronic components or the circuitry. The flexible areas can accommodate tight bends and twists, which is particularly beneficial in applications where the PCB needs to conform to a specific shape or fit into unconventional spaces.

The maximum layer count for this product reaches an impressive 52L, showcasing the extreme level of complexity and density that can be achieved. Such a high max layer count is indicative of the sophisticated technology that goes into the manufacturing of the 5. Flexible Printed Circuit Board- Rigid Flex. With more layers, designers have the freedom to incorporate additional features and capabilities into their electronics, making this product an excellent choice for highly advanced technological applications that require a multitude of connections and pathways.

The versatility of the Rigid Flex PCB is further emphasized through its capability to be used as a 3. Foldable Rigid-Flexible PCB. The foldable nature of this product means that it can be integrated into designs that require the PCB to be folded during either assembly or during its actual use. This is particularly useful in compact devices where space is at a premium, and the ability to fold the PCB allows for a more efficient use of available space.

In summary, the Rigid Flex PCB product is an embodiment of innovation, flexibility, and reliability. Its 4 Layer design, coupled with the option to expand up to 28 layers, provides a solid foundation for a multitude of electronic applications. The HASL LF surface finishing guarantees both performance and ecological responsibility. The carefully calibrated bend radius caters to the need for bendable and foldable PCB designs, while the potential to reach up to 52 layers of complexity caters to the most demanding and intricate electronic needs. Whether for consumer electronics, medical devices, or aerospace applications, the Rigid Flex PCB stands out as a superior choice, marrying the best of flexibility and rigidity in one streamlined product.

Features:

-

Product Name: Rigid Flex PCB

-

Pcb Layer: 1-28 layers

-

Hole Position Deviation: ±0.05mm

-

Minimum Trace/Space: 0.1mm

-

Flexibility: 1-8 Times

-

Surface Finishing: HASL LF

-

Multi-Layer Rigid and Flex Circuit Board

-

Bendable Rigid-Flex PCB

-

Foldable Rigid-Flexible PCB

Technical Parameters:

|

Attribute

|

Details

|

|

Dimension

|

41.55*131mm

|

|

Hole Position Deviation

|

±0.05mm

|

|

Material

|

FR4, Polyimide, PET

|

|

Flexibility

|

1-8 Times

|

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Surface Finishing

|

HASL LF

|

|

Sanforized

|

Local High Density, Back Drill

|

|

Product Type

|

PCB Assembly

|

|

Max Layer

|

52L

|

|

Profiling Punching

|

Routing, V-CUT, Beveling

|

Applications:

The Flexible Rigid Printed Circuit Board, which boasts a flexibility range of 1-8 times, is an innovative solution for electronic applications that require both rigidity and flexibility. The unique construction of this Rigid Flex PCB allows it to conform to different shapes and accommodate tight bend radii, ranging from 0.5 to 10mm, making it ideal for advanced electronic devices with complex layouts.

With the capability to support up to a 52L (52 Layer) configuration, the Multi-Layer Rigid and Flex Circuit Board opens up possibilities for sophisticated multi-layer designs. This is particularly beneficial for high-density applications where space is at a premium and performance is critical. The 4 Layer No Of Layers option serves as a standard offering for more routine applications, providing a blend of performance and cost-effectiveness.

The surface finishing of HASL LF (Hot Air Solder Leveling Lead-Free) on these boards ensures that they meet the latest environmental standards while providing reliable solderability and a long shelf life. This finishing technique is crucial for maintaining the functionality and integrity of the board throughout its operational lifespan, even under harsh conditions.

Application occasions for the Flexible Printed Circuit Board- Rigid Flex are diverse, ranging from consumer electronics, where the ability to fit into slim and irregularly shaped spaces is invaluable, to medical devices, which often require highly reliable and customizable circuitry. These boards are also crucial in military and aerospace applications, where their resilience and adaptability to extreme environments are necessary. In the automotive sector, the Rigid Flex PCB's ability to withstand vibrations and thermal stresses makes it ideal for in-vehicle systems.

Scenarios where the Rigid Flex PCB product truly shines include wearable technology, which demands electronics that can move and bend with the body without sacrificing performance. Smartphones, tablets, and other portable devices also benefit from the space-saving and flexible design possibilities. In industrial settings, the Rigid Flex PCB can be used in sensors and controls that require precise electronic pathways in three-dimensional spaces.

In conclusion, the Rigid Flex PCB, with its ability to combine flexibility and rigidity, a high number of layers, and a robust surface finish, is a versatile solution that meets the needs of various high-demand applications across different industries.

Customization:

Our

PCB Assembly

services offer extensive customization options to cater to your specific requirements. We specialize in the production of

2. Bendable Rigid-Flex PCBs

, which combine the best of both rigid boards and flexible circuits, providing unmatched versatility for your electronic projects.

With the ability to configure your

PCB Layer

count from 1-28 layers, our

4. Multi-Layer Rigid and Flex Circuit Boards

can be tailored to meet the complexities of your design, ensuring optimal performance and space utilization.

The

Bend Radius

of our PCBs can be customized between 0.5-10mm, allowing for precise control over the flexibility and bendability of the

2. Bendable Rigid-Flex PCB

. This feature is crucial for applications that require tight folding or space constraints.

We provide various options for

Surface Finishing

, including HASL LF (Lead-Free Hot Air Solder Leveling), which offers a reliable and environmentally friendly finish that ensures excellent solderability and long shelf life.

For precise board contouring, our

Profiling Punching

services include Routing, V-CUT, and Beveling. These techniques enable us to create custom shapes and sizes of the PCBs, ensuring a perfect fit for your application.

Support and Services:

Our Rigid Flex PCB product is supported by comprehensive technical support and services designed to ensure your success at every stage of your project. Our team of experts provides assistance with design considerations, material selection, and layout optimization to maximize the performance and reliability of your Rigid Flex PCB applications.

Technical support includes guidance on stack-up configuration, impedance control, and thermal management to help you tackle the unique challenges presented by the integration of rigid and flexible circuits. We also offer advice on proper handling and assembly techniques to prevent damage during manufacturing and assembly processes.

In addition to design and assembly support, we provide extensive testing services to ensure that your Rigid Flex PCB meets all performance criteria. This includes electrical testing, mechanical stress testing, and environmental testing to simulate real-world operating conditions.

Our commitment to your project's success is unwavering, and our support extends beyond the delivery of your Rigid Flex PCB. We are available to assist with any post-delivery inquiries, troubleshooting, and any further technical support services you may require to ensure the longevity and functionality of your product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!