Product Description:

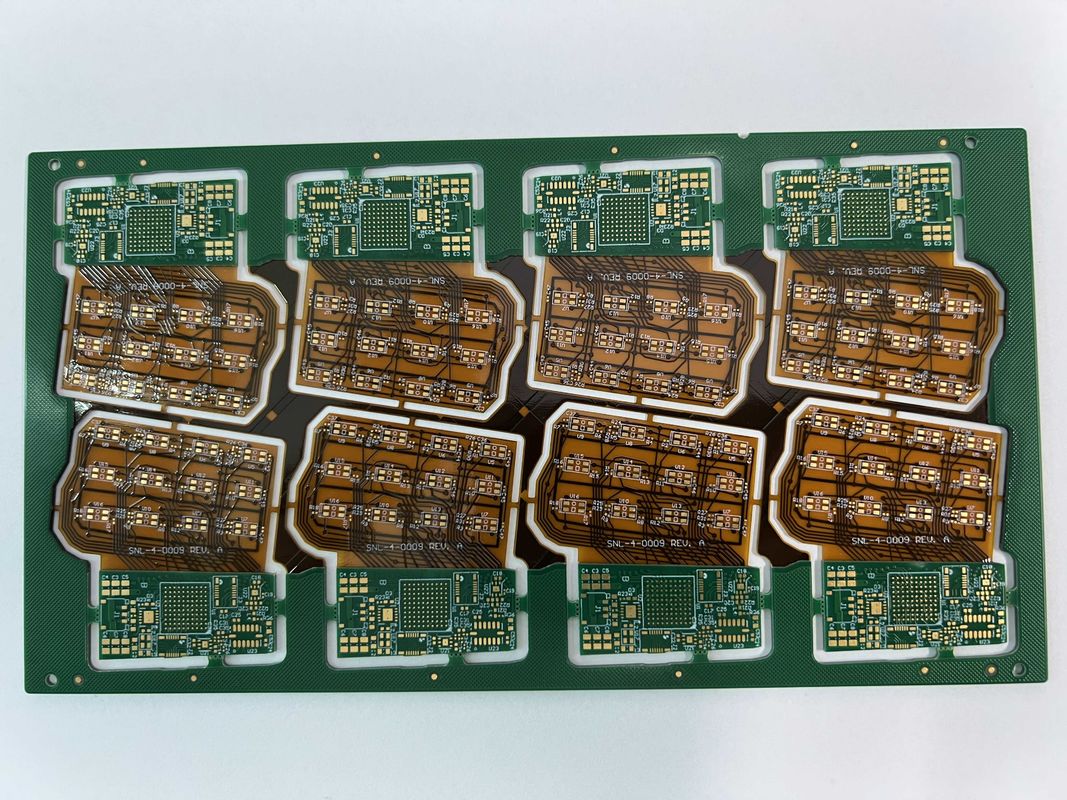

The Rigid Flex PCB, with its cutting-edge technology, is an exceptional product designed to meet the high demands of modern electronic devices. This 4 Layer PCB assembly combines the best of both rigid boards and flexible circuits, offering unparalleled flexibility and durability. With dimensions of 41.55*131mm, it fits seamlessly into a variety of applications, from intricate medical devices to robust aerospace components. The Rigid Flex PCB is a testament to the advancement in printed circuit board technology, providing a sophisticated solution for complex electronic challenges.

Constructed from high-quality materials such as FR4, Polyimide, and PET, the Rigid Flex PCB stands out in the market. FR4 offers excellent mechanical strength and thermal resistance, making it a standard for rigid PCBs. Polyimide, known for its reliability over a wide range of temperatures, is used in the flexible areas of the PCB. This allows for repeated bending and folding without compromising the circuit's integrity. PET, a cost-effective alternative, is also incorporated where flexibility and thermal stability are less critical. The combination of these materials results in a robust product that can withstand the rigors of daily use.

One of the standout features of this Rigid Flex PCB is its local high-density sanforization. This process enhances the PCB's reliability by reducing the chances of mechanical failures and improving electrical performance. It ensures that the high-density components are securely anchored, providing better protection against physical stress. Additionally, the back drill technology used in the PCB helps in minimizing signal integrity issues by removing any unnecessary stub in plated through-holes, which is essential for high-speed signal applications.

The versatility of this PCB assembly is further emphasized by its classification as a Bendable Rigid-Flex PCB. This product is specifically designed to sustain dynamic flexing - an essential feature for modern foldable and wearable electronics. It can bend at precise locations, allowing designers to create devices that can be flexed or folded without damage, thus enabling a new generation of electronic devices with movable parts.

As a Foldable Rigid-Flexible PCB, this product excels in applications that require the PCB to be folded during either assembly or operation. The foldable nature allows for a more compact and space-saving design, which is particularly advantageous in the miniaturization of electronic devices. The design of this PCB ensures that the folding does not lead to a compromise in the circuit's functionality or reliability, offering a seamless performance even in the most demanding situations.

Another key aspect of the Foldable Rigid-Flexible PCB is its ability to integrate multiple rigid boards into a single component, connected by flexible circuits that act as hinges. This reduces the need for connectors and cables, which not only saves space but also improves the overall mechanical stability and electrical performance of the device. This integration is critical in achieving a thinner, lighter, and more sophisticated product.

In summary, the Rigid Flex PCB is an innovative product that merges the strength of rigid boards with the adaptability of flexible circuits. Its dimensions, materials, and sanforization technique make it suitable for high-density applications where reliability and performance are paramount. Whether it's for the dynamic needs of a Bendable Rigid-Flex PCB or the compact designs of a Foldable Rigid-Flexible PCB, this assembly stands as a testament to the evolution of PCB technology, offering a reliable and efficient solution for today's electronic demands.

Features:

-

Product Name: Rigid Flex PCB

-

Max Layer: 52L

-

Product Type: PCB Assembly

-

Minimum Trace/Space: 0.1mm

-

Treatment: ENIG/OSP/Immersion Gold/Tin/Silver

-

No Of Layers: 4 Layer

-

Bendable Rigid-Flex PCB

-

Foldable Rigid-Flexible PCB

-

Multi-Layer Rigid and Flex Circuit Board

Technical Parameters:

|

Technical Parameter

|

Specification

|

|

Flexibility

|

1-8 Times

|

|

Hole Position Deviation

|

±0.05mm

|

|

Surface Finishing

|

HASL LF

|

|

Profiling Punching

|

Routing, V-CUT, Beveling

|

|

Minimum Trace/Space

|

0.1mm

|

|

Bend Radius

|

0.5-10mm

|

|

Pcb Layer

|

1-28layers

|

|

No Of Layers

|

4 Layer

|

|

Sanforized

|

Local High Density, Back Drill

|

|

Treatment

|

ENIG/OSP/Immersion Gold/Tin/Silver

|

Applications:

The Rigid Flex PCB, with its innovative blend of rigid and flexible board technologies, has found its way into numerous applications and scenarios that require the unique combination of sturdiness and flexibility. Profiling punching techniques such as routing, V-CUT, and beveling allow precise shaping and fitting of the PCB into complex enclosures, making the product ideal for sophisticated electronic devices. With a bend radius ranging from 0.5-10mm, the Bendable Rigid-Flex PCB can be tailored to fit into tight corners and accommodate moving parts without compromising the integrity of the circuit.

The surface finishing of HASL LF (Hot Air Solder Leveling Lead-Free) ensures that the board is reliable and adheres to modern environmental standards, while the sanforized feature allows for local high density and back drill, enhancing the electrical performance by reducing signal noise and improving signal integrity. The versatility of the PCB Layer, ranging from 1-28 layers, caters to a wide range of complexities, making the Multi-Layer Rigid and Flex Circuit Board suitable for various high-demand applications.

One of the primary application scenarios for the Bendable Rigid-Flex PCB is in wearable technology. Devices such as smartwatches and fitness trackers benefit from the PCB's ability to conform to ergonomic designs and endure the wear and tear of daily use. In the aerospace industry, the Multi-Layer Rigid and Flex Circuit Board is prized for its ability to withstand harsh conditions while maintaining a compact footprint, crucial for space-constrained onboard electronics. Similarly, in the medical field, the flexibility and reliability of the Rigid Flex PCB make it suitable for sensitive diagnostic equipment and portable medical devices where precision and dependability are paramount.

Moreover, in automotive applications, the Rigid Flex PCB's resistance to high temperatures and vibrations makes it an excellent choice for in-vehicle systems, such as infotainment and navigation units. The board's ability to be folded or bent means it can conform to the intricate shapes within a vehicle's dashboard or control panels. Lastly, in the realm of consumer electronics, the Rigid Flex PCB is instrumental in creating sleek, compact devices like smartphones and tablets, where space is at a premium, and performance cannot be compromised.

In conclusion, the Rigid Flex PCB with its advanced features like profiling punching, optimal bend radius, superior surface finishing, and multi-layer capabilities, is a key component in modern electronics, finding utility in diverse fields that demand both the strength of a rigid board and the adaptability of a flexible one.

Customization:

Our Rigid Flex PCB product offers an exceptional range of customization services to meet the versatile needs of our customers. With a

Max Layer

capacity of

52L

, we can accommodate complex and high-density designs. Precision is key in PCB manufacturing, and we ensure a

Hole Position Deviation

tolerance of

±0.05mm

for high-accuracy requirements.

We are equipped to handle various

Components

such as

SMD, BGA, DIP

, and more, providing versatility in your PCB assembly options. Our

Surface Finishing

process utilizes

HASL LF

(Lead-Free Hot Air Solder Leveling), ensuring environmentally friendly and reliable boards.

The

No Of Layers

option for this product starts at a

4 Layer

configuration, catering to both simple and complex designs. As a leading provider of the

5. Flexible Printed Circuit Board- Rigid Flex

, we take pride in delivering PCBs that seamlessly integrate the durability of rigid boards with the adaptability of flex circuits.

Choose our Rigid Flex PCB customization services for a product that embodies the reliability and innovative design encapsulated in the

5. Flexible Printed Circuit Board- Rigid Flex

. Our commitment is to provide a

5. Flexible Printed Circuit Board- Rigid Flex

that meets the exacting standards of your industry and application.

Support and Services:

Rigid Flex PCB products combine the best of both rigid boards and flexible circuits integrated together into one unit, allowing for a more complex design in a smaller footprint. Our technical support and services for Rigid Flex PCBs ensure that your product is designed and manufactured to the highest standards. We provide comprehensive support throughout the design process, including material selection, stack-up, impedance calculations, and design for manufacturability (DFM) advice.

During the manufacturing process, our services include state-of-the-art fabrication with precise alignment of the flexible layers to the rigid parts, advanced drilling and plating techniques, and stringent quality control measures. We also offer testing services, such as electrical tests to ensure functionality and reliability, as well as mechanical testing to gauge flexibility and durability.

Our after-sales support includes troubleshooting assistance, guidance for proper handling and storage of Rigid Flex PCBs to maintain their integrity, and recommendations for any necessary repairs or modifications. We are committed to providing extensive support and services to ensure the optimal performance and longevity of your Rigid Flex PCB products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!