Product Description:

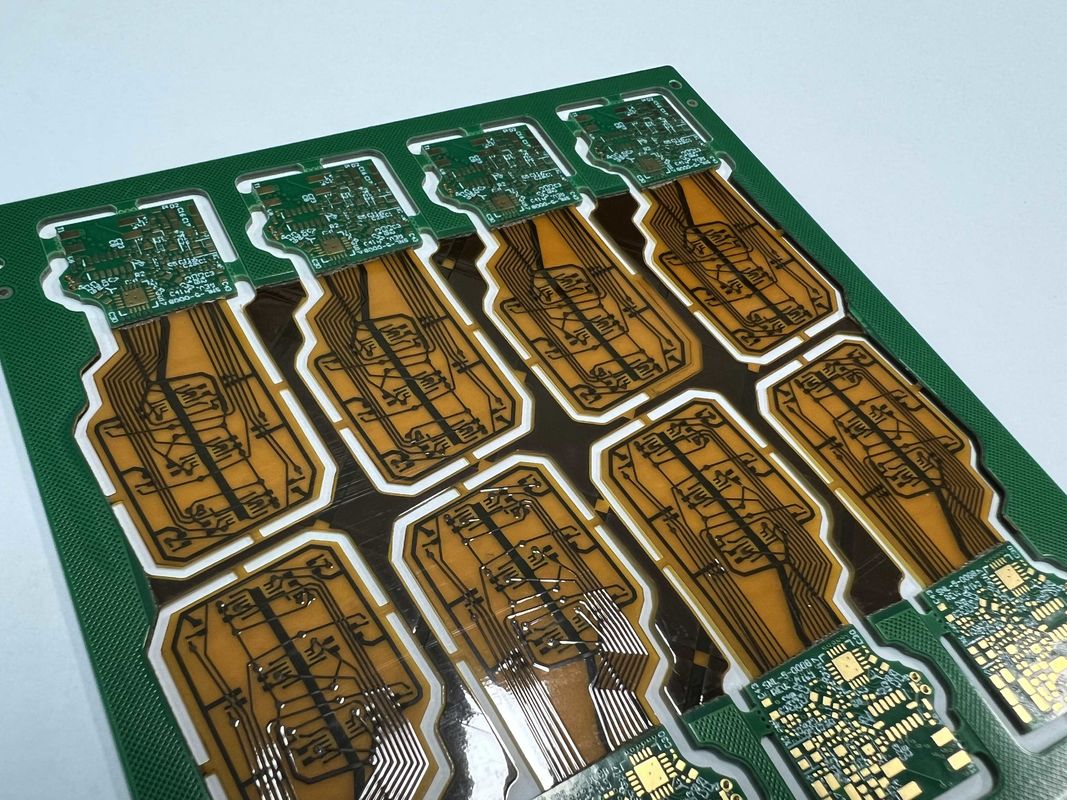

The Rigid Flex PCB is an advanced solution that embodies the perfect blend of stability and flexibility, specifically designed to cater to the demanding needs of modern electronics. The intricate design of this Flexible Rigid Printed Circuit Board spans a dimension of 41.55*131mm, providing ample space for complex circuits while maintaining a sleek, compact form factor. This product stands out in the market as a hallmark of innovation, especially for applications requiring the delicate balance between rigid and flexible circuitry.

One of the most notable features of this Rigid Flex PCB is its superior surface finishing. Employing Hot Air Solder Leveling (HASL) with Lead-Free (LF) technology, the product ensures exceptional solderability and reliability for all your connections. This environmentally friendly surface finishing technique not only provides a robust shield against corrosion but also promotes the durability and longevity of the product, making it an ideal choice for a wide array of applications.

As a PCB Assembly product, this Rigid Flex PCB is designed for seamless integration into your projects. It is engineered to serve as the backbone of your electronic devices, offering a solid platform for various components to work in unison. The construction of this PCB combines the sturdiness of traditional rigid boards with the versatility of flexible circuits, allowing it to be folded or bent to fit into tight spaces without compromising the integrity of the electrical connections – a feature that gives rise to its classification as a Foldable Rigid-Flexible PCB.

The manufacturing process adheres to stringent quality standards, achieving a Minimum Trace/Space of 0.1mm. This fine line technology enables the PCB to support local high-density interconnects, giving you the freedom to design intricate and compact electronic circuits. The precision in trace and space dimensions is critical for high-speed signal transmission and miniaturization of electronic devices, thereby enhancing the overall performance and reliability of the final product.

Moreover, the Rigid Flex PCB incorporates a specialized technique known as back drilling. This advanced method involves removing non-functional copper from drilled holes to reduce signal integrity issues such as reflections and losses, particularly crucial in high-frequency applications. The back drilling process ensures that your signals have a clear path with minimal disturbance, which is vital for maintaining the integrity of high-speed data transfer and reducing noise in the circuit.

The application of sanforization to the Rigid Flex PCB is another testament to its high-quality design. This process locally enhances the density of the board, reinforcing the areas that require additional structural support while maintaining overall flexibility. This attribute is especially useful in complex electronic assemblies where certain regions face higher mechanical stresses or where additional support is needed for mounted components.

In summary, the Rigid Flex PCB is an exemplary product that brings together the best attributes of rigid and flexible printed circuit technologies. Its 41.55*131mm dimension, HASL LF surface finishing, and 0.1mm minimum trace/space specifications make it a highly adaptable and reliable solution for a vast range of electronic applications. The inclusion of sanforization for local high-density support and back drilling for signal integrity makes this PCB an exceptional choice for designers and engineers seeking a Foldable Rigid-Flexible PCB that offers both high performance and versatility.

Features:

-

Product Name: Rigid Flex PCB

-

Surface Finishing: HASL LF

-

Bend Radius: 0.5-10mm

-

Product Type: PCB Assembly

-

Material: FR4, Polyimide, PET

-

Sanforized: Local High Density, Back Drill

-

1. Flexible Rigid Printed Circuit Board

-

5. Flexible Printed Circuit Board- Rigid Flex

Technical Parameters:

|

Attribute

|

Specification

|

|

Product Type

|

PCB Assembly

|

|

Material

|

FR4, Polyimide, PET

|

|

Hole Position Deviation

|

±0.05mm

|

|

No Of Layers

|

4 Layer

|

|

Surface Finishing

|

HASL LF

|

|

Treatment

|

ENIG/OSP/Immersion Gold/Tin/Silver

|

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Flexibility

|

1-8 Times

|

|

Minimum Trace/Space

|

0.1mm

|

|

Profiling Punching

|

Routing, V-CUT, Beveling

|

Applications:

The Flexible Rigid Printed Circuit Board (PCB) is a sophisticated and versatile solution designed to cater to a wide range of applications that require the combination of sturdy and flexible design elements. This hybrid construction allows the PCB to be partially flexible, enabling it to fit into tight spaces and conform to various shapes while maintaining the rigidity needed for certain components. With PCB layers ranging from 1-28, these boards are suitable for both simple and complex electronic circuits.

Product type is a critical consideration, and the Rigid Flex PCB excels in the PCB Assembly category. It is often utilized in electronic devices where space is at a premium and reliability is paramount. The ability to assemble components on a board that can bend or fold without compromising the integrity of the circuit is invaluable in modern electronics design.

The Rigid Flex PCB is treated with various surface finishes such as ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), Immersion Gold, Tin, or Silver. These treatments are selected based on the requirements of the application, such as the need for corrosion resistance, ease of soldering, or wire bondability. This versatility ensures that the boards can be optimized for a wide range of environmental conditions and manufacturing processes.

One of the defining features of the Rigid Flex PCB is its bend radius, which can range from 0.5 to 10mm. This flexibility allows the board to be bent or folded to conform to the confines of the product without compromising performance. This feature is particularly useful in applications such as wearable technology, aerospace, and medical devices where the PCB must adapt to ergonomic designs or specific spatial constraints.

Moreover, the Rigid Flex PCB is designed to accommodate local high density and can include back drilling to remove any unnecessary via stubs, thereby improving signal integrity in high-speed designs. This level of customization is essential in applications such as telecommunications, military, and sophisticated consumer electronics where performance and reliability are critical.

The Multi-Layer Rigid and Flex Circuit Board is an advanced type of PCB that offers numerous advantages for complex electronic systems. These boards are commonly used in industries where the electronic devices are subject to constant movement or flexing, as well as environments that require the miniaturization of electronic components. The integration of multiple layers allows for a higher density of interconnections, making the Multi-Layer Rigid and Flex Circuit Board ideal for sophisticated devices such as smartphones, cameras, and advanced automotive systems.

Customization:

Our Product Customization Services for the Rigid Flex PCB product cater to your specific needs with a maximum layer count of 52L. We specialize in designing 4 Layer Multi-Layer Rigid and Flex Circuit Boards tailored to high-performance standards.

Our 4 Layer Multi-Layer Rigid and Flex Circuit Board is not only robust but also provides localized high-density features and back drilling options to ensure efficient signal integrity and mechanical reliability.

With our advanced manufacturing processes, we maintain a hole position deviation of ±0.05mm, guaranteeing precise alignment and fit for your PCB Assembly requirements.

Choose our expertise for your PCB Assembly needs and experience the unparalleled quality of our 4 Layer Multi-Layer Rigid and Flex Circuit Board customization services.

Support and Services:

Our Rigid Flex PCB products are supported by a comprehensive technical support and service package designed to ensure reliability, performance, and customer satisfaction. Our technical support team is equipped with extensive expertise in Rigid Flex PCB technology and is ready to assist with any queries or issues that may arise.

Support services include product consultation to help with design considerations, material selection, and layout optimizations. We also offer detailed documentation and resources to guide you through the installation and maintenance processes of your Rigid Flex PCB.

In the event of any performance concerns or technical difficulties, our technical support team provides troubleshooting assistance to diagnose and resolve issues promptly. We are committed to providing effective solutions and advice to maintain the integrity and longevity of your Rigid Flex PCB applications.

To further ensure the highest quality standards, our Rigid Flex PCBs undergo rigorous testing and quality control measures. Our services include post-production support to address any concerns related to the manufacturing process or the functionality of the product in its operational environment.

Our goal is to offer an exceptional customer experience through our dedicated support and service offerings for Rigid Flex PCB products. We strive to ensure that our customers have all the necessary support to achieve optimal performance and reliability from their Rigid Flex PCBs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!