Product Description:

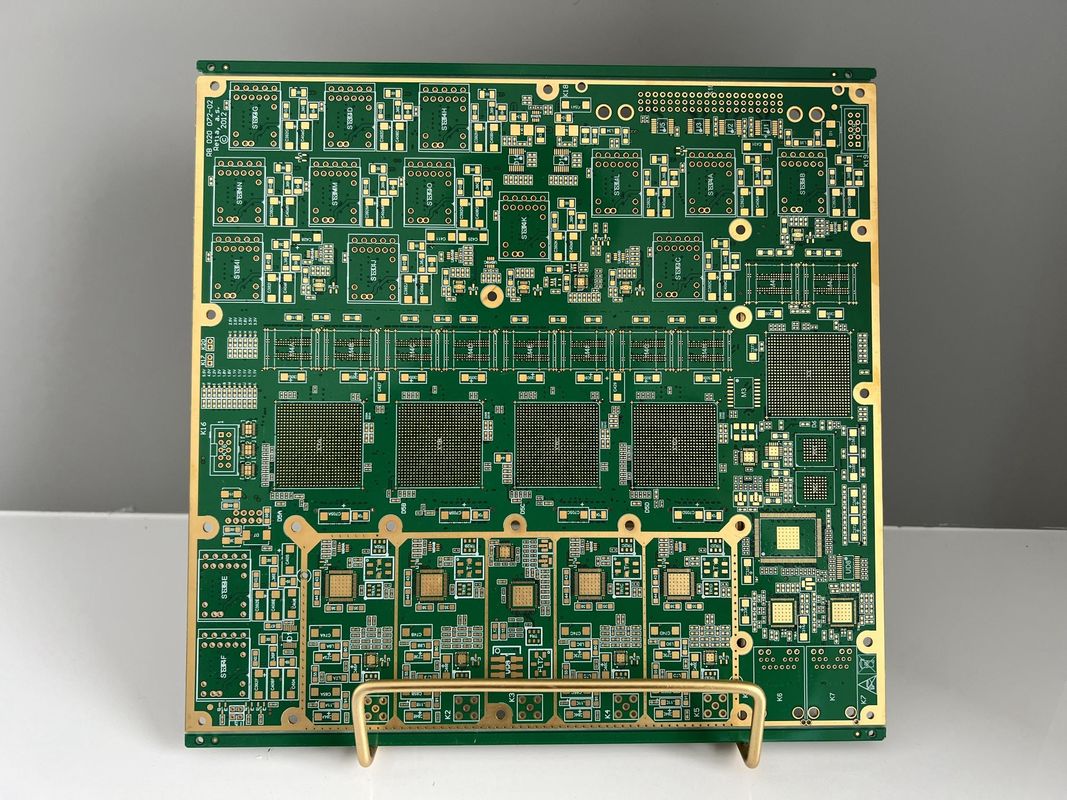

The HDI Any Layer PCB provides enhanced impedance control, which is crucial for high-speed digital and RF applications. The impedance control ensures that the signal integrity is maintained throughout the circuit board, resulting in better reliability and performance.

The HDI Any Layer PCB is available with a lead time of 2-5 days, which makes it ideal for time-sensitive projects. The short lead time ensures that the PCBs can be manufactured and delivered quickly, reducing the overall time-to-market.

The HDI Any Layer PCB is designed to support any layer count, which means that it can be customized to meet the specific requirements of the application. This flexibility in layer count makes it possible to create complex designs and incorporate high-density components, resulting in a smaller, more compact device.

The HDI Any Layer PCB is available in various solder mask colors, including green, red, blue, black, yellow, and white. The solder mask color helps to identify the different components and layers on the board, making it easier to troubleshoot and repair any issues.

The HDI Any Layer PCB has a minimum annular ring of 3mil, which is the smallest ring that can be created between the copper pad and the drilled hole. The small annular ring size allows for the placement of more components on the board, resulting in a more compact design.

Features:

- Product Name: HDI Any Layer PCBs

- Min. Finished Hole Size: 0.1mm

- Testing: Flying Probe Test, E-test

- Lead Time: 2-5 Days

- Copper Weight: 0.5oz-6oz

- Thickness: 0.2mm-6.0mm

- Features:

- Multilayer Interconnect System

- High-Density Integrated Circuit Interconnection Board

- High-Density Wiring Board

Technical Parameters:

| Product Attribute |

Value |

| Product Name |

High-Density Assembly System |

| Product Type |

Any-Layer Interconnect Board |

| Thickness |

0.2mm-6.0mm |

| Min. Finished Hole Size |

0.1mm |

| Lead Time |

2-5 Days |

| Material |

FR-4 |

| Testing |

Flying Probe Test, E-test |

| Layer Count |

Any Layer |

| Solder Mask Color |

Green, Red, Blue, Black, Yellow, White |

| Minimum Line Width/Spacing |

3mil/3mil |

| Minimum Hole Size |

0.1mm |

| Silkscreen Color |

White, Black, Yellow |

| Product Description |

Miniature Interconnect System |

Applications:

The solder mask color options of green, red, blue, black, yellow, and white allow for customization to fit different product designs and aesthetics. The minimum line width and spacing of 3mil/3mil ensures that the board can handle high-density wiring requirements.

The use of the HDI Any Layer PCBs product can be seen in various scenarios. For example, it can be used in medical devices where space is a premium, and precision is a must. The product can also be used in telecommunications where high-speed data transfer is required.

The silkscreen color options of white, black, and yellow allow for clear labeling of components and identification of different sections of the board.

In summary, the HDI Any Layer PCBs product is a versatile and customizable option for those seeking a high-density wiring board for use in a multilayer interconnect system. Its ability to accommodate any layer count and impedance control, combined with its various color options, makes it suitable for a wide range of product application occasions and scenarios.

Customization:

Our Multilayer High-Density Printed Circuit Board (PCB) product, specifically the Any Layer PCBs, can be customized to fit your specific needs. We offer customization services for layer count, with Any Layer options available, as well as material selection with FR-4 being a popular choice. You can also choose from a variety of silkscreen colors such as White, Black, and Yellow. We guarantee a minimum annular ring of 3mil and offer Impedance Control as an additional customization option. These features make our Miniature Interconnect System and High-Density Interconnect Board a perfect fit for your project. Contact us today to discuss your customization needs.

Support and Services:

The HDI Any Layer PCBs product technical support and services include:

- Expert consultation on design and material selection

- Prototype fabrication and testing

- PCB manufacturing and assembly

- Quality control and inspection

- Product warranty and repair services

- Technical documentation and training

Our team of experienced engineers and technicians are dedicated to providing exceptional support and services to ensure the success of your project. Contact us for more information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!