Product Description:

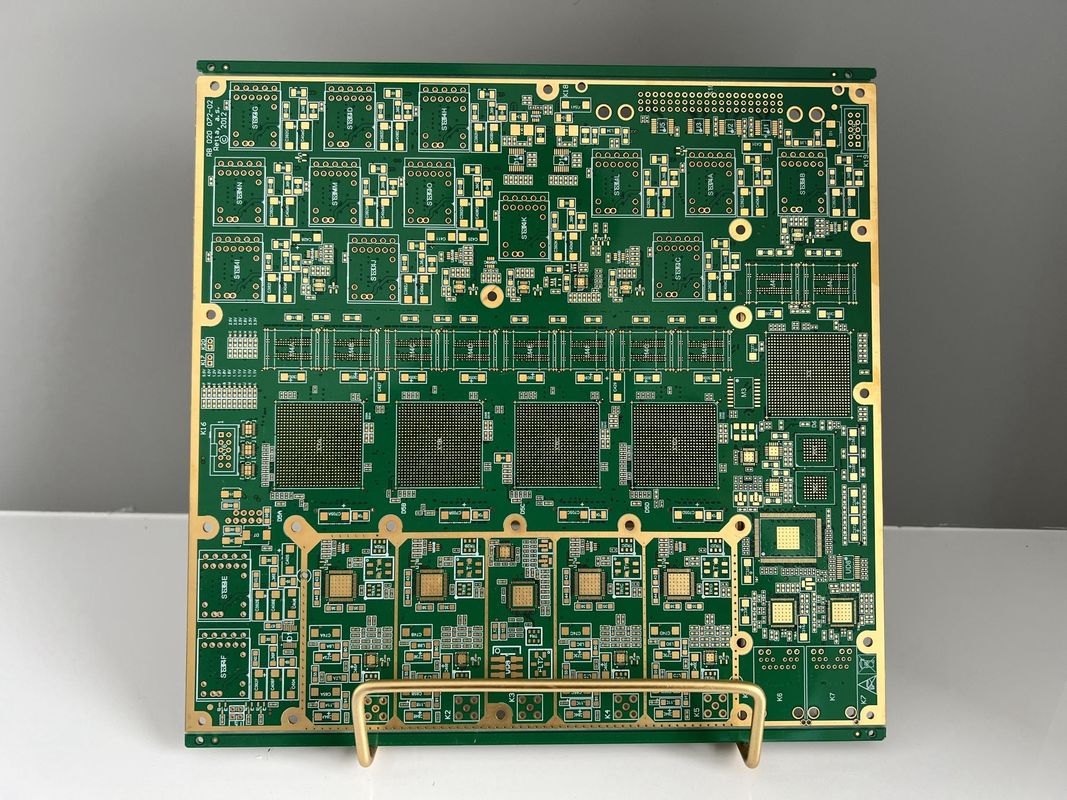

The High-Density Interconnect (HDI) Any Layer Printed Circuit Boards (PCBs) are at the pinnacle of PCB technology, catering to complex and high-density wiring board projects across various industries. These boards are designed to meet the stringent requirements of high-speed, high-frequency applications where space, weight, and performance are critical factors. With the ability to have any number of layers, these HDI Any Layer PCBs offer unparalleled design flexibility, making them an excellent choice for advanced electronic assemblies.

One of the most notable features of the HDI Any Layer PCBs is their extensive layer count capability. This allows for a significant amount of circuitry to be compressed into a small form factor, which is essential for modern electronic devices that require complex wiring and high functionality. The any layer technology enables connections to be made between any layers of the PCB, which optimizes the signal integrity and electrical performance of the final product.

In terms of surface finishes, the HDI Any Layer PCBs come with a variety of options to choose from, including Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Immersion Silver, and Organic Solderability Preservatives (OSP). Each of these surface finishes offers unique benefits. HASL is cost-effective and provides good solderability, while ENIG offers excellent corrosion resistance and is ideal for fine-pitch components. Immersion Silver is known for its excellent flatness and conductivity, and OSP provides a clean, lead-free surface that's suitable for complex soldering requirements.

Copper weight is another critical attribute of these high-density wiring boards. With options ranging from 0.5oz to 6oz, HDI Any Layer PCBs can accommodate various current-carrying requirements, ensuring that they can be tailored to suit both the power and signal needs of the application. Heavier copper weights are particularly beneficial in applications where thermal management is a concern, as they help dissipate heat more effectively.

Impedance control is a critical specification in the design and production of HDI Any Layer PCBs. These boards are engineered with precision to ensure that the impedance of the traces and vias meets the specific requirements of the application. This is crucial for maintaining signal integrity, especially in high-speed and high-frequency circuits where any deviation can result in signal loss or reflection.

Moreover, the aesthetic and functional aspects of the HDI Any Layer PCBs are addressed with the availability of various silkscreen colors, including white, black, and yellow. The silkscreen layer is essential for adding human-readable markings on the PCB, such as component identifiers and test points, which facilitate easier assembly and troubleshooting. The choice of color can enhance the visibility of these markings or provide a specific look to match the branding or design preferences of the end product.

The High Density Interconnect Any Layer PCBs represent a leap forward in PCB manufacturing, accommodating the evolving demands for more compact, efficient, and high-performing electronics. These boards are particularly suitable for applications in telecommunications, medical devices, military and aerospace, and any other field where advanced electronic packaging is required. With their excellent interconnect reliability, high layer counts, and superior electrical characteristics, HDI Any Layer PCBs are a strategic choice for designers looking to push the boundaries of electronic design and achieve a competitive edge in their respective markets.

In conclusion, the High Density Interconnect Any Layer PCBs are a testament to the advancements in PCB technology. They offer a combination of high layer count, versatile surface finishes, substantial copper weight options, stringent impedance control, and a range of silkscreen colors, making them a customizable solution for complex and high-density wiring board requirements. Whether you are working on a cutting-edge consumer electronic device or a critical aerospace component, HDI Any Layer PCBs provide the reliability, performance, and precision needed to bring your innovative projects to life.

Features:

- Product Name: HDI Any Layer PCBs

- High-Density Interconnect Board

- Multilayer High-Density Printed Circuit Board

- Any-Layer Interconnect Board

- Silkscreen Color: White, Black, Yellow

- Min. Annular Ring: 3mil

- Minimum Hole Size: 0.1mm

- Testing: Flying Probe Test, E-test

- Solder Mask Color: Green, Red, Blue, Black, Yellow, White

Technical Parameters:

| Technical Parameter |

Specification |

| Minimum Line Width/Spacing |

3mil/3mil |

| Material |

FR-4 |

| Silkscreen Color |

White, Black, Yellow |

| Copper Weight |

0.5oz-6oz |

| Layer Count |

Any Layer |

| Min. Finished Hole Size |

0.1mm |

| Lead Time |

2-5 Days |

| Testing |

Flying Probe Test, E-test |

| Thickness |

0.2mm-6.0mm |

| Surface Finish |

HASL, ENIG, Immersion Silver, OSP |

Applications:

The HDI (High-Density Interconnect) Any Layer PCB is a sophisticated Multilayer High-Density Printed Circuit Board that is specifically designed to meet the complex needs of modern electronics. The product attributes such as a minimum annular ring of 3mil, the utilization of the FR-4 material, impedance control, and a minimum line width/spacing of 3mil/3mil, make it an ideal choice for a wide range of applications and scenarios.

One of the primary application occasions for the HDI Any Layer PCBs is in the realm of high-performance computing. The high density of these boards enables them to support the latest generation of processors and memory modules, which require a Multilayer High-Density Printed Circuit Board to handle multiple signals at high speeds. The precise impedance control ensures signal integrity for high-speed data transfers, making these boards perfect for servers, data centers, and supercomputers.

Moreover, the High-Density Interconnect Board is crucial in the field of telecommunications. Devices such as smartphones, tablets, and other wireless communication systems benefit from the compact size and enhanced electrical performance that these PCBs provide. The HDI Any Layer PCBs allows for a denser layout of components, which is essential for portable electronics that have limited space but require high functionality.

In the medical industry, the High Density Interconnect Any Layer PCBs are used in critical medical equipment. Devices such as MRI machines, CT scanners, and other diagnostic tools rely on the high precision and reliability these PCBs offer. The ability to withstand Flying Probe Testing and E-testing ensures that each board meets the stringent requirements necessary for medical applications.

Furthermore, these PCBs are also prevalent in the automotive sector, where advanced electronics are increasingly common. From engine control units to infotainment systems, the HDI Any Layer PCBs provide the reliability and durability needed to withstand the harsh environments encountered in automotive applications.

Lastly, aerospace and defense systems also utilize the High Density Interconnect Any Layer PCBs for their advanced electronic systems. These sectors require components that can operate reliably under extreme conditions, and the robustness of the FR-4 material combined with the high-density interconnect capabilities makes these PCBs an obvious choice.

In conclusion, the HDI Any Layer PCBs are versatile and can be applied in various high-tech industries due to their superior electrical performance, reliability, and scalability. Whether it's computing, telecommunications, medical, automotive, or aerospace and defense, these Multilayer High-Density Printed Circuit Boards are engineered to perform under the most demanding circumstances.

Customization:

Our HDI Any Layer PCBs offer a range of Product Customization Services to meet the exacting needs of high-density assembly systems. We provide comprehensive testing options, including both Flying Probe Test and E-test, to ensure that each Any-Layer Interconnect Board meets our rigorous quality standards.

The minimum finished hole size we can achieve is as small as 0.1mm, enabling high-density integrated circuit interconnection board designs that require precise and intricate patterns. Our solder mask color options include Green, Red, Blue, Black, Yellow, and White, giving you the flexibility to select the perfect aesthetic for your project.

We also cater to various requirements in terms of copper weight, ranging from 0.5oz up to 6oz, to accommodate different current-carrying capacities and durability needs. Additionally, our technology allows for a minimum line width and spacing of 3mil/3mil, which is crucial for the intricate designs associated with Any-Layer Interconnect Boards.

Support and Services:

Our HDI Any Layer PCBs come with comprehensive technical support and services to ensure the highest level of satisfaction. With our state-of-the-art High-Density Interconnector (HDI) technology, we can support complex designs with high reliability and precision. Our support includes:

Design Consultation: Our team of experts is available to help with PCB design considerations, ensuring that your layout is optimized for HDI Any Layer technology.

Manufacturing Support: We guide you through the manufacturing process, providing insights into material selection, layer stack-up, and process capabilities to meet your requirements.

Quality Assurance: Our products undergo rigorous testing and quality control procedures to guarantee that they meet all industry standards and your specific quality requirements.

Technical Documentation: We provide detailed documentation covering specifications, handling instructions, and guidelines for best practices during assembly and integration.

After-Sales Support: Our commitment to you continues after delivery with after-sales support to address any concerns or issues that may arise during the use of our HDI Any Layer PCBs.

For any technical questions or assistance with your HDI Any Layer PCBs, our dedicated support team is ready to help you achieve the best possible performance from your product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!