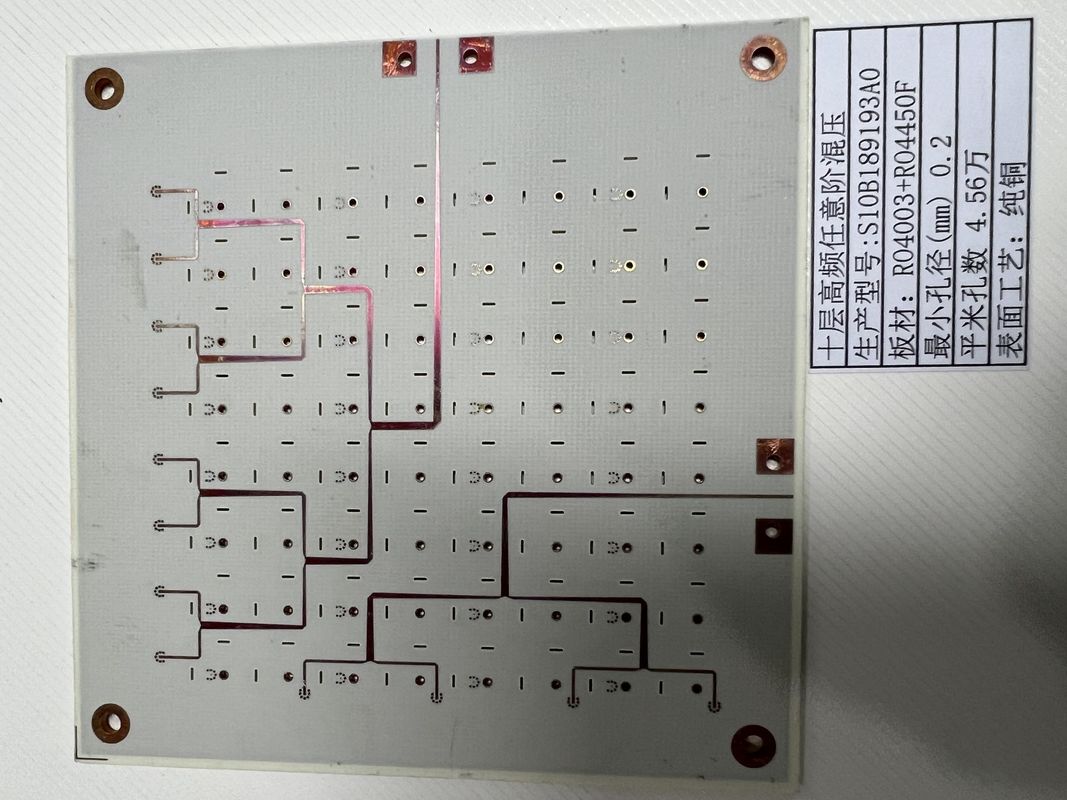

Advanced HDI FR-4 PCBs with Impedance Control Flying Probe Test 0.5oz-6oz Copper Weight

Product Description:

The HDI Any Layer PCBs represent a significant advancement in the technology of printed circuit boards, offering unparalleled performance and versatility. Designed to meet the rigorous demands of the modern electronics industry, these PCBs are an ideal solution for applications requiring high-density interconnections and reliable signal integrity. The Any-Layer Interconnect Board is a product that caters to a wide range of technologies, from sophisticated communication devices to critical medical equipment.

At the heart of the HDI Any Layer PCB is the meticulous Impedance Control, ensuring that the electrical characteristics of the board match the precise requirements of the application. This is critical for maintaining signal integrity, especially in high-speed digital applications. Impedance control is not just a feature; it is a guarantee that the performance of the board will meet the exacting standards necessary for today's complex electronic assemblies.

The material used in the construction of these Multilayer High-Density Printed Circuit Boards is the industry-standard FR-4. This material is chosen for its excellent electrical insulation, mechanical strength, and thermal endurance. It is capable of withstanding the stresses of assembly and the rigors of operation in a wide range of environments. FR-4 is a tried and tested material that provides a stable and reliable foundation for high-density interconnect systems.

With copper weights ranging from 0.5oz to 6oz, these boards offer great versatility. The varying copper weights allow for a wide range of current-carrying capacities, which means that the HDI Any Layer PCBs can be tailored to suit power-heavy applications or fine-pitch precision circuits. This flexibility in design is one of the reasons why these boards are a preferred choice for engineers and designers seeking to optimize their electronic assemblies for performance and reliability.

One of the most remarkable features of the HDI Any Layer PCBs is their Min. Finished Hole Size of 0.1mm. This capability allows for extremely fine pitch components to be used, enabling designers to pack more functionality into smaller spaces. This is a critical advantage in industries where miniaturization is key, such as in mobile devices and wearable technology. The ability to create such small vias is a testament to the precision manufacturing processes employed in the production of these boards.

Understanding the importance of time-to-market in the competitive electronics industry, the lead time for the HDI Any Layer PCBs is kept within a very efficient window of 2-5 days. This rapid turnaround time ensures that projects remain on schedule and can respond quickly to market demands. Whether it's for prototyping or full-scale production, the swift lead time is an essential factor in maintaining the momentum of product development cycles.

The Multilayer Interconnect System embodied by HDI Any Layer PCBs is a testament to the evolution of PCB technology. It provides designers with the flexibility to create more complex and more powerful electronic systems than ever before. With its robust impedance control, versatile FR-4 material, a range of copper weights, and ultra-fine hole capabilities, the HDI Any Layer PCB is a cornerstone of modern electronic design. Whether for aerospace, automotive, consumer electronics, or any other industry where reliability and density are paramount, these PCBs stand as a beacon of innovation and quality.

In conclusion, the HDI Any Layer PCBs are not just another component in the electronics supply chain; they are a pivotal element in the advancement of electronic technology. They enable the creation of the Multilayer High-Density Printed Circuit Board systems that power today's and tomorrow's innovations. With the combination of quality materials, precise manufacturing, and rapid lead times, these PCBs are set to be at the forefront of the electronics industry for years to come.

Features:

- Product Name: HDI Any Layer PCBs

- Layer Count: Any Layer

- Surface Finish: HASL, ENIG, Immersion Silver, OSP

- Solder Mask Color: Green, Red, Blue, Black, Yellow, White

- Min. Annular Ring: 3mil

- Impedance Control: Yes

- High-Density Wiring Board

- Multilayer Interconnect System

- Advanced Multilayer Interconnect System

Technical Parameters:

| Parameter |

Specification |

| Lead Time |

2-5 Days |

| Silkscreen Color |

White, Black, Yellow |

| Copper Weight |

0.5oz-6oz |

| Impedance Control |

Yes |

| Material |

FR-4 |

| Thickness |

0.2mm-6.0mm |

| Min. Finished Hole Size |

0.1mm |

| Surface Finish |

HASL, ENIG, Immersion Silver, OSP |

| Minimum Hole Size |

0.1mm |

| Layer Count |

Any Layer |

Applications:

The HDI Any Layer PCBs, characterized by their Any-Layer Interconnect Board technology, offer a versatile solution for a wide range of applications. These PCBs are designed to accommodate any layer count, making them ideal for sophisticated electronic devices where space is at a premium and performance is critical. The PCBs' silkscreen color options include white, black, and yellow, allowing for clear labeling and identification in various operational environments.

With copper weights ranging from 0.5oz to 6oz, these High-Density Interconnect boards deliver the necessary power and signal integrity for high-current applications and fine-pitch components. Such flexibility in copper weight also enables designers to balance the PCB's thermal management requirements with the mechanical strength needed for the end-use scenario.

The minimum hole size of 0.1mm on the HDI Any Layer PCBs underscores the board's capacity for high-density component placement. This feature is especially important in applications where real estate is at a premium, such as in mobile devices, wearable technology, and medical implants.

Depending on the specific application, the surface finish of the HDI Any Layer PCBs can be tailored to meet the requirements of the product. Options include Hot Air Solder Leveling (HASL) for cost-effectiveness, Electroless Nickel Immersion Gold (ENIG) for excellent surface planarity, Immersion Silver for a balance between cost and performance, and Organic Solderability Preservatives (OSP) for a lead-free and clean surface finish.

These Any-Layer Interconnect Boards are particularly suited for industries that require high-reliability and dense packaging, such as aerospace, military, and high-end computing. They are also commonly used in smartphones, tablets, and other consumer electronics where miniaturization and high-speed signal transmission are essential. The automotive industry, too, benefits from the use of HDI Any Layer PCBs in advanced driver-assistance systems (ADAS), infotainment systems, and electronic control units (ECUs) that demand robust and reliable interconnect solutions.

In summary, the versatility in layer count, silkscreen color, copper weight, minimum hole size, and surface finish options make HDI Any Layer PCBs an ideal choice for a multitude of scenarios where high-density interconnect technology is a fundamental requirement for product success.

Customization:

The HDI Any Layer PCBs , also known as High-Density Integrated Circuit Interconnection Boards, are the pinnacle of sophistication in PCB technology. Our product customization services allow for a wide range of specifications to meet your precise needs. With a thickness range of 0.2mm-6.0mm , these any-layer interconnect boards can be tailored to fit compact and diverse applications.

Our High-Density Integrated Circuit Interconnection Boards boast a minimum annular ring of 3mil , ensuring reliable connections and robust performance for your high-precision requirements. Additionally, we offer a variety of solder mask colors to choose from including Green, Red, Blue, Black, Yellow, and White , allowing for personalized aesthetic preferences and board identification.

The Layer Count is fully customizable, supporting Any Layer configurations for complex and advanced circuit designs. This flexibility ensures that our HDI Any Layer PCBs can accommodate the most intricate layouts and functionalities.

Understanding the importance of time in product development, we offer a rapid lead time of 2-5 days , making sure that your project moves forward without delay. Our product customization services for HDI Any Layer PCBs combine quality, precision, and speed to help you achieve your project goals with efficiency.

Support and Services:

Our HDI Any Layer PCBs are designed to offer superior performance for high-density applications. In order to ensure your satisfaction and the optimal functioning of your product, we provide comprehensive technical support and services. Our team of experts is equipped to assist you with any technical questions or issues you may encounter with your HDI Any Layer PCBs.

Our services include detailed product documentation, troubleshooting guides, and application notes to facilitate self-help. Additionally, we offer direct support for more complex inquiries or issues that may arise during the use of our product. Our technical team is committed to helping you understand the full capabilities of your HDI Any Layer PCBs and to resolve any problems promptly and efficiently.

To enhance the performance of your HDI Any Layer PCBs, we also provide advice on best practices for design, layout, and assembly. We are dedicated to ensuring that you can leverage the full potential of our technology in your applications. Please note that while we strive to provide extensive support, our services may vary depending on the specific requirements and configurations of your product.

If you require further assistance, please feel free to reach out to our customer service team (contact information excluded). We are here to support you every step of the way, from initial design to final production, ensuring your HDI Any Layer PCBs meet your expectations and contribute to the success of your projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!