Product Description:

The Rogers PCB Board is a state-of-the-art High Frequency Circuit Board tailored for applications that demand high performance and reliability. At the heart of this board is the Rogers R3003 High Frequency PCB material, which is renowned for its exceptional dielectric properties and its ability to maintain signal integrity in demanding environments. With a dielectric constant (Dk) range of 2.55-10.2, this PCB is capable of meeting a wide array of design requirements, making it an ideal choice for high-frequency and fast signal speed applications.

When it comes to durability and longevity, the Rogers PCB Board does not disappoint. It comes with a variety of surface finish options to suit different applications. These include Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), Immersion Silver, Immersion Tin, and Hard Gold. These surface finishes not only protect the copper from oxidation but also provide a reliable surface for soldering components. The gold surface option further enhances the board's conductivity and makes it suitable for high-wear uses, such as keypads or high-use switches.

In addition to its impressive electrical properties, the Rogers PCB Board is visually customizable. It offers a range of solder mask colors, including traditional Green, sleek Black, vibrant Blue, Yellow, and Red, ensuring that the board meets both the functional and aesthetic requirements of various applications. Whether for a specific color coding of PCBs or for matching corporate branding, the color options allow for a high degree of personalization.

The Rogers RF Circuit Board is not just about its high-frequency capabilities and aesthetic customization; it also provides excellent legibility for component identification and marking. The silkscreen, which is used to print information such as component outlines and identifiers on the PCB, is available in White, Black, and Yellow. These options ensure clear contrast and visibility, which is essential for assembly, inspection, and maintenance.

Furthermore, the Rogers RF Circuit Board's design is executed with precision and attention to detail. The advanced manufacturing processes used to produce these boards ensure tight tolerances and high levels of consistency. This attention to quality extends to the board's thermal management capabilities, providing stable performance even under variable temperature conditions. The Rogers PCB Board's thermal properties make it a go-to choice for applications across industries, including aerospace, telecommunications, automotive, and medical devices.

The reliability of the Rogers PCB Board is also underpinned by its robust solder mask, which provides an additional layer of protection against environmental factors, such as dust, moisture, and chemical contaminants. This ensures that the board's performance is maintained over time, even in harsh conditions. Additionally, the variety of surface finishes contributes to the board's solderability, ensuring strong and reliable connections between the PCB and its components.

In summary, the Rogers PCB Board combines the high-performance characteristics of the Rogers R3003 High Frequency PCB material with the versatility of multiple surface finishes and customization options. Its wide dielectric constant range, coupled with the availability of different solder mask colors and silkscreen options, makes it an adaptable and reliable choice for a host of high-frequency applications. Whether you are designing complex RF circuitry or simply require a PCB that can maintain signal integrity at high speeds, the Rogers PCB Board is engineered to exceed expectations and deliver unmatched performance.

Features:

- Product Name: Rogers PCB Board

- Glass Epoxy: RO4730G3 0.762mm

- PCB Thickness: 1.6mm

- Solder Mask: Green, Black, Blue, Yellow, Red, etc.

- Material: Rogers R5880

- Copper Thickness: 0.5-6oz

- Rogers Electronic Printed Board: High-quality board for stable electronic applications

- High Frequency Circuit Board: Ideal for high-speed and high-frequency circuit designs

- Rogers Electronic Printed Board: Renowned for reliable and efficient performance

Technical Parameters:

| Technical Parameter |

Specification |

| Pcb Thickness |

1.6mm |

| Test |

100% Electrical Test Prior Shipment |

| Based Material |

CLTE-XT 1.016mm |

| Silkscreen Color |

White, Black, Yellow |

| Surface Finish |

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Hard Gold |

| Silkscreen |

White |

| Coverlay Colour |

Yellow |

| Size |

According To Customer Request |

| Dielectric Constant |

2.55-10.2 |

| Glass Epoxy |

RO4730G3 0.762mm |

Applications:

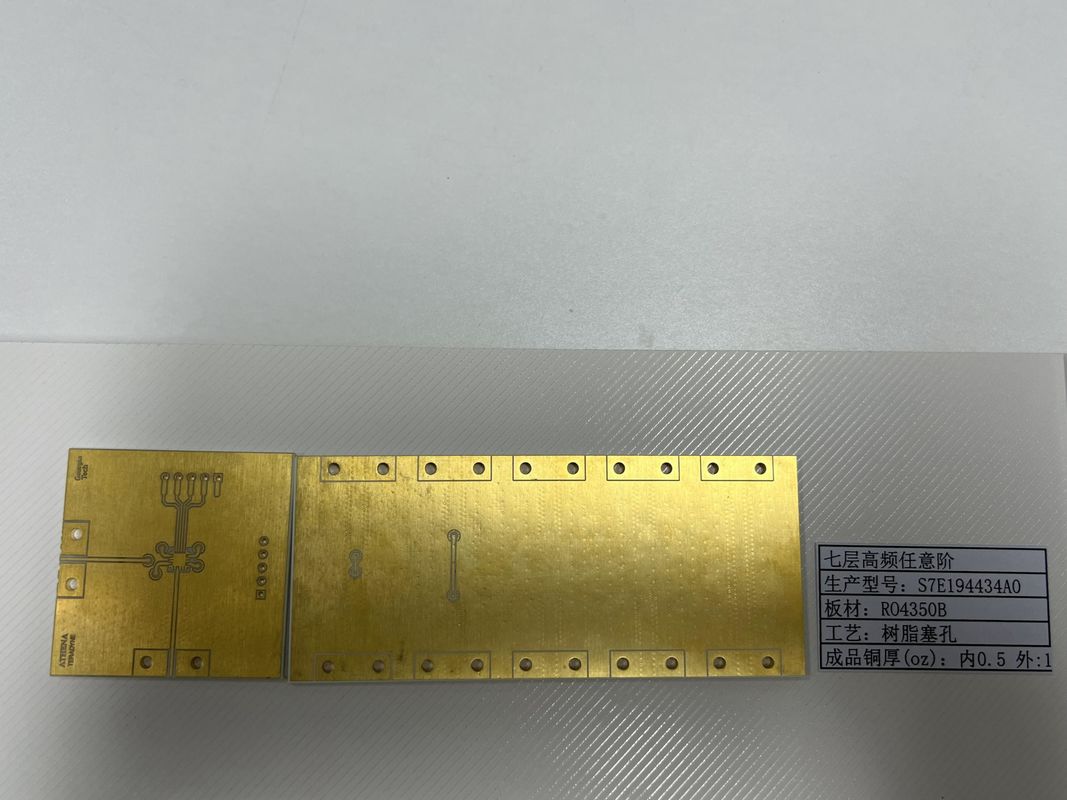

The Rogers PCB Board, adorned with a lustrous gold surface and pristine white silkscreen, stands as a testament to high-quality circuitry solutions. This board, available with a variety of surface finishes such as HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and Hard Gold, is engineered to meet the rigorous standards of multiple advanced electronic applications. Every Rogers PCB Board undergoes a 100% electrical test prior to shipment, ensuring that each unit functions flawlessly upon delivery. With copper thickness options ranging from 0.5 to 6oz, this product is incredibly versatile and can be tailored to a wide array of electrical requirements.

One prominent application of the Rogers PCB Board includes the Rogers+FR4 Multilayer PCB, which is extensively used in high-speed digital and analog systems where signal integrity is paramount. This hybrid construction offers superior electrical performance and enhanced thermal management, making it ideal for telecommunications equipment, aerospace avionics, and automotive radar systems. The multilayer design is also beneficial in dense circuit layouts found in high-performance computing and networking hardware.

For microwave and RF applications, the Rogers R5880 PCB is the go-to choice. Its low dielectric loss allows for efficient signal transmission at high frequencies, which is crucial for applications such as satellite communications, cellular base stations, and microwave links. The Rogers R5880 PCB's consistency in dielectric constant over a wide frequency range makes it exceptionally reliable for critical communication infrastructure and sophisticated radar systems.

Moreover, the Rogers R4350B PCB is renowned for its high thermal conductivity and low thermal expansion, which suits it for applications that involve substantial fluctuations in temperature. This includes LED lighting systems, high-power amplifiers, and industrial sensors. The board's robustness makes it an excellent candidate for harsh environments where reliability over extended periods is necessary.

In summary, the Rogers PCB Board, with its advanced material properties and meticulous testing regimen, is a versatile solution for a multitude of scenarios ranging from consumer electronics to specialized industrial applications. Its customization in terms of surface finishes and copper thickness further solidifies its position as a premier choice for designers and engineers seeking top-tier PCB performance.

Customization:

Customize your Rogers PCB Board to meet your specific electronic design requirements. Our Product Customization Services offer a range of options to create the perfect Rogers Electronic Printed Board for your project. Select from a variety of copper thicknesses ranging from 0.5oz to 6oz to ensure your Rogers High Frequency Printed Board performs with the necessary conductivity and thermal properties.

Choose from multiple surface finish options such as HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and Hard Gold to enhance the solderability and longevity of your Rogers Electronic Board. Our surface finishes are carefully applied to provide optimal electrical performance and reliability.

Our solder mask options include an array of colors like Green, Black, Blue, Yellow, Red, etc., providing not only protection against oxidation and bridging between solder joints but also allowing you to customize the aesthetics of your board according to your preferences or coding systems.

All of our customized Rogers PCB Boards come with the assurance of a 100% Pass Electrical Test, ensuring that your board functions correctly right from the start. Additionally, we offer a distinctive yellow coverlay color, providing your board with a professional and high-quality finish.

Support and Services:

The Rogers PCB Board is supported by a comprehensive range of technical support and services to ensure the highest level of performance and reliability. Our team of experts is dedicated to providing you with the support you need to address any technical challenges you may encounter. The following services are included:

Technical Consultation: Our skilled engineers are available to provide insights and advice on PCB design, material selection, and performance optimization to ensure that your Rogers PCB Board meets your application requirements.

Design Review Services: Before production, our team offers a thorough review of your PCB designs to identify potential issues that could affect manufacturability or performance, helping to minimize risks and reduce costs.

Material Selection Assistance: With a variety of Rogers materials available, we can help you select the most appropriate substrate for your application, considering factors such as dielectric constant, loss tangent, and thermal performance.

Prototyping Services: To validate your design before full-scale production, we offer rapid prototyping services that enable quick turnaround times and high-quality prototypes that reflect the final product's performance.

Thermal Management Solutions: Our experts can assist with thermal analysis and provide solutions to manage heat dissipation, which is critical for the longevity and reliability of your Rogers PCB Board.

Quality Assurance: We are committed to delivering high-quality products and employ rigorous testing and quality control measures in accordance with industry standards to ensure that your Rogers PCB Board meets your expectations.

Documentation and Resources: A library of technical documentation, datasheets, and application notes is available to provide you with detailed information about the Rogers PCB Board and its use in various applications.

Please note that while we strive to provide comprehensive support, some services may be subject to availability and may require additional lead time. We recommend reaching out to our technical support team for specific inquiries and tailored assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!