Product Description:

The Rogers PCB Board, an exceptional offering in the realm of High Frequency Circuit Boards, stands out with its superior quality and reliability, catering to a wide range of high-speed design requirements. This High Frequency Printed Circuit Board is meticulously engineered with the esteemed CLTE-XT base material, boasting a thickness of 1.016mm. The Rogers High Frequency Printed Board has been designed to meet the advanced needs of modern electronics where performance and durability are paramount.

At the core of the Rogers PCB Board is the CLTE-XT material which provides an excellent foundation for High Frequency Circuit Boards. This base material is renowned for its low thermal expansion coefficient, ensuring stability and integrity of the board even under thermal stress. With a dielectric constant range of 2.55-10.2, the Rogers PCB Board delivers consistent electrical performance across a wide spectrum of frequencies, making it an ideal choice for RF and microwave applications.

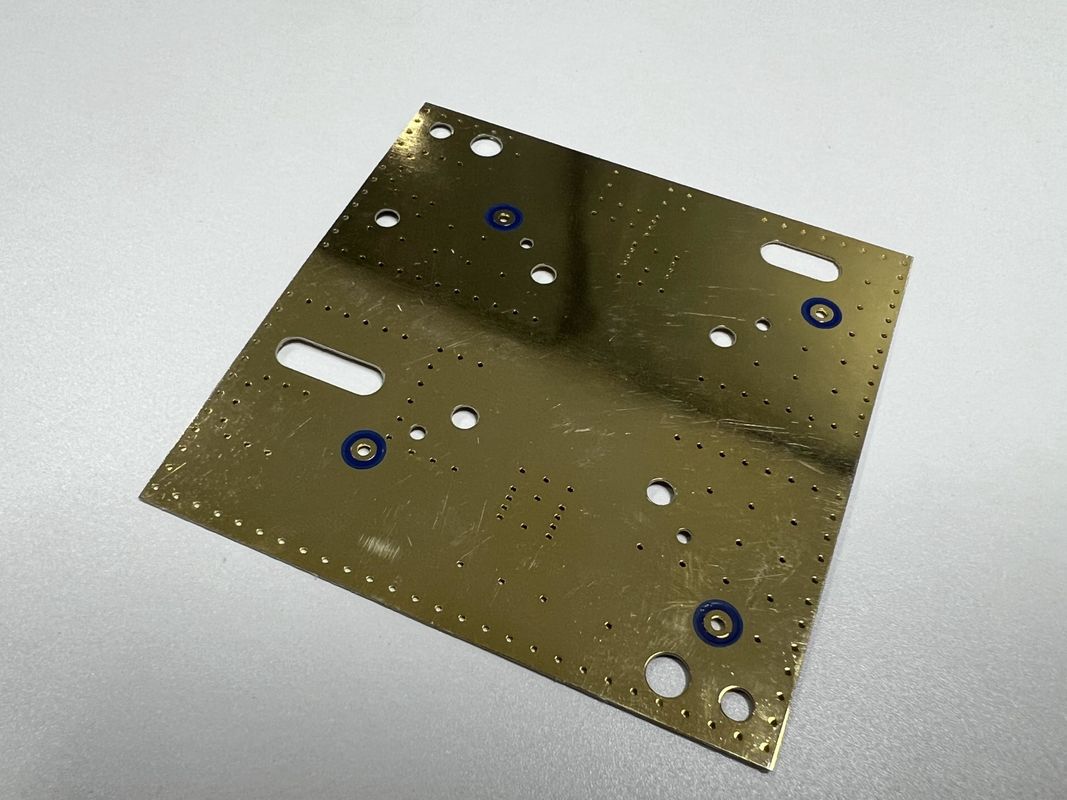

Surface quality is another critical aspect where the Rogers PCB Board excels. The board comes with a gold surface that not only offers a regal appearance but also provides excellent conductivity and resistance to oxidation, ensuring longevity and consistent performance over time. The quality of the surface is pivotal in High Frequency Printed Circuit Boards as it directly affects signal integrity and reduces the risk of signal loss or degradation.

One of the remarkable features of the Rogers PCB Board is the variety of surface finishes available. Customers can select from a range of finishes including Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), Immersion Silver, Immersion Tin, and Hard Gold. Each of these finishes caters to different requirements providing options for enhanced solderability, corrosion resistance, and wire bondability. This versatility ensures that the Rogers High Frequency Printed Board can be customized to fulfill the specific needs of any high-performance application.

Customization does not end with surface finishes; the Rogers PCB Board is also offered in various sizes tailored according to customer requests. This level of customization is crucial for diverse applications ranging from telecommunications to aerospace, where each sector has its unique size constraints and installation environments. The ability to customize the dimensions of the High Frequency Circuit Board allows for seamless integration into existing systems and devices without the need for extensive redesigns or adjustments.

The Rogers PCB Board, with its high-quality material, precise dielectric constant, and customizable size and surface finishes, is a prime example of a High Frequency Printed Circuit Board that delivers reliability and performance. Whether it's for demanding commercial applications or critical military systems, the Rogers High Frequency Printed Board is engineered to provide the highest level of satisfaction in terms of durability, functionality, and efficiency. The commitment to excellence in every aspect of the board's design and manufacturing process assures that customers receive a product that not only meets but exceeds their expectations for high-frequency applications.

Features:

- Product Name: Rogers PCB Board

- Function: 100% Pass Electrical Test

- Material: Rogers R4350B

- Size: According To Customer Request

- Test: 100% Electrical Test Prior Shipment

- Solder Mask: Green, Black, Blue, Yellow, Red, etc.

- High Frequency Circuit Board

- Rogers+FR4 Multilayer PCB

- Rogers Laminated PCB

Technical Parameters:

| Attribute |

Specification |

| Coverlay Colour |

Yellow |

| Based Material |

CLTE-XT 1.016mm |

| Material |

Rogers R4350B |

| Surface |

Gold |

| Copper Thickness |

0.5-6oz |

| Dielectric Constant |

2.55-10.2 |

| Silkscreen Color |

White, Black, Yellow |

| Function |

100% Pass Electrical Test |

| Test |

100% Electrical Test Prior Shipment |

| Silkscreen |

White |

Applications:

The Rogers PCB Board, customized to fit the precise needs of various industries, is a versatile and high-quality product catering to an array of applications. This Rogers+FR4 Multilayer PCB is specifically designed for scenarios where the reliability and performance of the electronic components are paramount. The surface finish options available, including HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and Hard Gold, provide the board with excellent surface planarity, good solderability, and low contact resistance, which are essential attributes for high-reliability sectors such as aerospace, military, and medical devices.

With a standard PCB thickness of 1.6mm and the ability to customize the size according to customer requests, the Rogers Electronic Board is adaptable to various design specifications and can be integrated seamlessly into both standard and bespoke electronic assemblies. The available copper thickness range from 0.5 to 6oz allows for high current applications and ensures that the board can handle significant power loads, making it suitable for power amplifiers and radio frequency applications.

The High Frequency Circuit Board's silkscreen color options — white, black, and yellow — provide excellent contrast and visibility for marking components, test points, and important information, which is crucial during the assembly and inspection processes. This feature simplifies the complex assembly processes often encountered in telecommunications equipment and high-speed digital applications.

The Rogers PCB Board is an ideal choice for industries that require high-frequency performance and thermal management. Its use in satellite communications, microwave links, and cellular base station hardware underscores its ability to maintain signal integrity in the most demanding environments. The product's attributes, such as superior dielectric constant and thermal performance provided by the Rogers material, combined with the robustness offered by FR4, make this Rogers+FR4 Multilayer PCB a reliable substrate for advanced electronics that operate under extreme conditions.

In summary, the Rogers PCB Board is a product that excels in various applications and scenarios. Whether it is for advanced communication systems, high-speed networks, or sensitive signal processing units, the combination of Rogers material with multilayer FR4 technology presents a solution that engineers and designers can trust for their most critical and high-performance circuit board requirements.

Customization:

Our Rogers PCB Board product offers a range of Product Customization Services to cater to your specific needs. The board, known for its exceptional performance in high-frequency electronic applications, can be tailored with the following attributes:

Silkscreen: A crisp, white silkscreen is applied to ensure clear labelling and professional aesthetics on your Rogers High Frequency Electronic Board.

PCB Thickness: The standard 1.6mm thickness provides a robust foundation for your Rogers mixed stack up PCBs, balancing durability with functionality.

Surface Finish: Choose from a variety of surface finishes including HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and Hard Gold to meet the specific requirements of your Rogers Laminate Board.

Coverlay Colour: A vibrant yellow coverlay is used to protect the circuitry while adding a distinctive look to your customized board.

Size: We accommodate all size requirements According To Customer Request, ensuring your Rogers PCB Board fits perfectly into its intended application.

Support and Services:

The Rogers PCB Board is supported by a comprehensive suite of technical support and services designed to ensure the highest level of performance and satisfaction. Our product experts are dedicated to providing assistance with product specifications, installation guidance, troubleshooting, and performance optimization.

For technical inquiries regarding the Rogers PCB Board, customers can access a wealth of resources including detailed product documentation, FAQs, application notes, and technical papers that provide in-depth information on product features and best practices for implementation.

To further support our customers, we offer advanced services such as thermal analysis, signal integrity simulations, and material compatibility testing to ensure that the Rogers PCB Board meets the specific requirements of your applications. Our commitment to quality is reflected in our ongoing research and development efforts to enhance product capabilities and introduce innovative solutions.

We encourage customers to utilize our online support forums where they can engage with a community of experts and peers to share insights, discuss challenges, and find solutions related to the Rogers PCB Board. Our technical support team actively monitors these forums to provide additional expertise and assistance when needed.

Please note that while we strive to provide comprehensive support, our services do not include in-person technical service or on-site repairs. Customers are advised to contact their local authorized distributor or our customer service team for information on returns or warranty-related queries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!