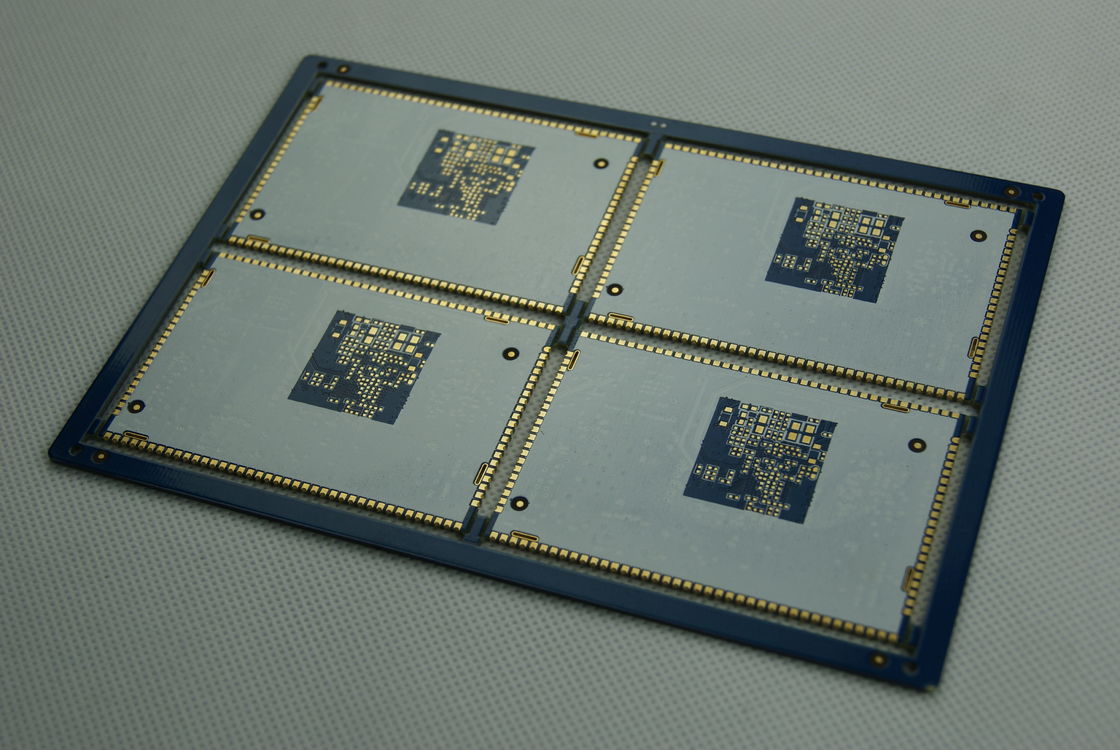

Advanced Multilayer PCB Board Four sides half holes Glass Epoxy FR-4 HASL Surface Coating

Product Description:

The Multilayer PCB Board, a remarkable and highly sophisticated component in the electronics industry, stands as a testament to the advancements in circuit technology. With the integration of up to 20 Layers PCBs, this product offers unmatched performance and reliability for a wide range of applications, from critical medical devices to high-performance computing systems. Our company takes pride in providing a one-stop service OEM solution, ensuring that every aspect of the PCB manufacturing process is streamlined, efficient, and tailored to meet our customers' unique requirements.

Constructed using the advanced glass epoxy material RO4003C combined with Tg170 FR-4, the Multilayer PCB Board delivers exceptional electrical properties and thermal stability. This combination is specifically chosen to withstand the rigorous demands of high-speed circuitry, providing a reliable substrate that maintains integrity under thermal stresses. The Tg170 FR-4 material further enhances the board's durability, making it resistant to the harsh environments and thermal cycles that electronics often encounter.

One of the critical attributes of the Multilayer PCB Board is its copper weight, which stands at an impressive 12OZ. This substantial copper weight is indicative of the board's ability to handle high current applications with ease, reducing the risk of thermal strain and ensuring efficient power distribution across the entire circuit. The heavy copper construction is ideal for applications that require robust power converters, high-current outputs, or intricate thermal management solutions.

As electronic devices become increasingly compact and complex, the need for precision engineering in PCBs becomes paramount. Our Multilayer PCB Board boasts a minimum hole size of 0.2mm, demonstrating our commitment to precision and our capability to accommodate intricate designs with high-density interconnects (HDI). This fine level of detail is essential for modern electronics where space is at a premium and every millimeter of the board must be optimized for signal integrity and connectivity.

The versatility of the Multilayer PCB Board is further enhanced by the range of copper thicknesses available, from 0.5oz to 6oz. This allows for customization based on the specific electrical requirements of the application. Whether it's a 12 Layers PCBs for moderate complexity devices or the full 20 Layers PCBs for the most demanding projects, our product can be tailored to ensure optimal performance. The thicker copper layers are particularly beneficial for high-power circuits, where increased copper thickness can significantly improve the current carrying capacity and heat dissipation.

Our Multilayer PCB Board is a product of meticulous engineering and state-of-the-art manufacturing processes, ensuring that every board meets the highest standards of quality and reliability. We understand that in the world of electronics, there is no room for error. That's why our PCBs undergo rigorous testing and quality control measures to guarantee that they perform as expected in the most critical applications.

In conclusion, the Multilayer PCB Board is the embodiment of high-tech circuitry and engineering excellence. With features like 20 Layers PCBs, 12 Layers PCBs, 12OZ copper weight, RO4003C+ Tg170 FR-4 glass epoxy, a minimum hole size of 0.2mm, and copper thickness options ranging from 0.5oz to 6oz, this PCB is designed to meet the needs of the most demanding electronic applications. Our one-stop service OEM approach ensures that every client receives a customized, high-quality product that is not only robust but also highly efficient and reliable. The Multilayer PCB Board is undoubtedly a cornerstone in modern electronics, enabling innovation and performance that drive the industry forward.

Features:

- Product Name: Multilayer PCB Board

- Surface Finishing Options:

- HASL (Hot Air Solder Leveling)

- Immersion Gold

- Immersion Tin

- Immersion Silver

- Gold Finger

- OSP (Organic Solderability Preservatives)

- Max. Panel Size: 600mm*1200mm

- Layers: 4-22 Layer Multilayer PWB

- Copper Thickness: 0.5oz-6oz

- Packing: Vacuum Packing With Carton Box

- Also known as Multilayer Circuit Board

- Designed with Multilayer Circuitry Board technology

Technical Parameters:

| Technical Parameter |

Specification |

| Copper Thickness |

0.5oz-6oz |

| Glass Epoxy |

RO4003C+ Tg170 FR-4 |

| Number Of Layers |

4-22 Layers |

| Copper Weight |

12OZ |

| Min. Hole Size |

0.2mm |

| Size |

/ |

| Thickness |

0.2mm-6.0mm |

| Layers |

4-22 Layer |

| Max. Panel Size |

600mm*1200mm |

| Surface Mount Technology |

Yes |

Applications:

The Multilayer PCB Board, with its substantial copper weight of 12OZ, is a robust and versatile component essential for various high-demand applications. Its multilayered design, often referred to as a Multilayer PWB (Printed Wiring Board), enables it to support complex circuits while maintaining a compact form factor, making it an ideal solution for a wide range of electronic devices.

One of the key application occasions for these Multilayer PCB Boards is in the realm of consumer electronics. As devices continue to shrink in size while growing in complexity, the need for 10 Layers PCBs becomes increasingly crucial. Smartphones, laptops, and wearable technology such as smartwatches and fitness trackers all benefit from the space-saving and performance-boosting features that these multilayer circuit boards provide. The high copper weight ensures excellent conductivity for power distribution and signal integrity, which is paramount in these high-performance devices.

In the industrial sector, the Multilayer Circuit Board finds its significance in managing intricate systems that require reliability and durability. Heavy machinery, automation equipment, and robotics systems often incorporate these PCBs to handle the high power and complex circuitry needed for operation. The large max. panel size of 600mm*1200mm available for these PCBs allows for extensive circuit designs that can accommodate a multitude of components necessary for sophisticated industrial applications.

The telecommunications industry also benefits from the advanced capabilities of Multilayer PWBs. High-speed servers, routers, and switches rely on the exceptional electrical properties and the ability to create dense interconnections that these boards offer. The minimum hole size of 0.2mm ensures that even the smallest components can be integrated into the design, which is critical for the high-density packaging required in telecommunications equipment.

Additionally, the Multilayer PCB Board is a staple in the medical device sector, where precision and reliability are non-negotiable. Medical imaging equipment, diagnostic instruments, and patient monitoring systems all make use of 10 Layers PCBs for their complex electronic needs. The one-stop service OEM offering for these PCBs streamlines the design and manufacturing process, allowing for tailored solutions that meet the stringent requirements of medical technology.

In summary, the extensive application scenarios for Multilayer PCB Boards underscore their importance in modern electronics. From consumer gadgets to industrial control systems, and from telecommunications to medical devices, these PCBs are fundamental in enabling the sophisticated functionality that defines our current technological landscape. With the ability to handle significant copper weights and support intricate designs, Multilayer PWBs are at the heart of innovation across various sectors.

Customization:

Our Multilayer PCB Board product offers a range of customization services to meet your specific project requirements. With a minimum hole size of 0.2mm, we ensure precision and reliability in the most complex Multilayer Circuit Board designs.

Our boards can be customized with thicknesses ranging from 0.2mm to 6.0mm, accommodating various applications from lightweight devices to more robust systems. While the size of the PCB can be tailored to your needs, we are capable of producing Multilayer PWBs up to a maximum panel size of 600mm*1200mm.

Additionally, we provide advanced Surface Mount Technology services, ensuring your Multilayer Printed Circuit Board is equipped for modern electronic components and design specifications.

Support and Services:

Our Multilayer PCB Board comes with comprehensive technical support and services designed to ensure reliability, performance, and customer satisfaction. Our support includes:

Product Documentation: We provide detailed documentation, including specifications, installation guides, and user manuals to assist with product understanding and handling.

Troubleshooting Assistance: In case of any issues, our expert team is available to guide you through troubleshooting procedures to quickly identify and resolve any potential problems with your Multilayer PCB Board.

Technical Inquiry: For any technical questions or concerns, our knowledgeable support staff can provide in-depth insights and clarifications regarding the Multilayer PCB Board's features and use.

Firmware and Software Updates: We offer regular updates to firmware and software to enhance functionality, improve performance, and ensure the highest level of security for your device.

Repair Services: Should your Multilayer PCB Board require repair, we provide professional repair services to restore your product to its optimal working condition.

Replacement Parts: In the event that any component of your Multilayer PCB Board requires replacement, we supply genuine parts to ensure compatibility and performance.

Product Training: We offer training sessions for individuals or teams to ensure that you are fully equipped to utilize all the features and capabilities of your Multilayer PCB Board.

Warranty Support: Our Multilayer PCB Board is backed by a warranty that covers defects in materials and workmanship. We stand behind our product and provide warranty support in accordance with our stated terms and conditions.

We are committed to providing exceptional service and support to ensure that you get the most out of your Multilayer PCB Board. Our team is dedicated to your satisfaction and is here to assist with any needs that may arise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!