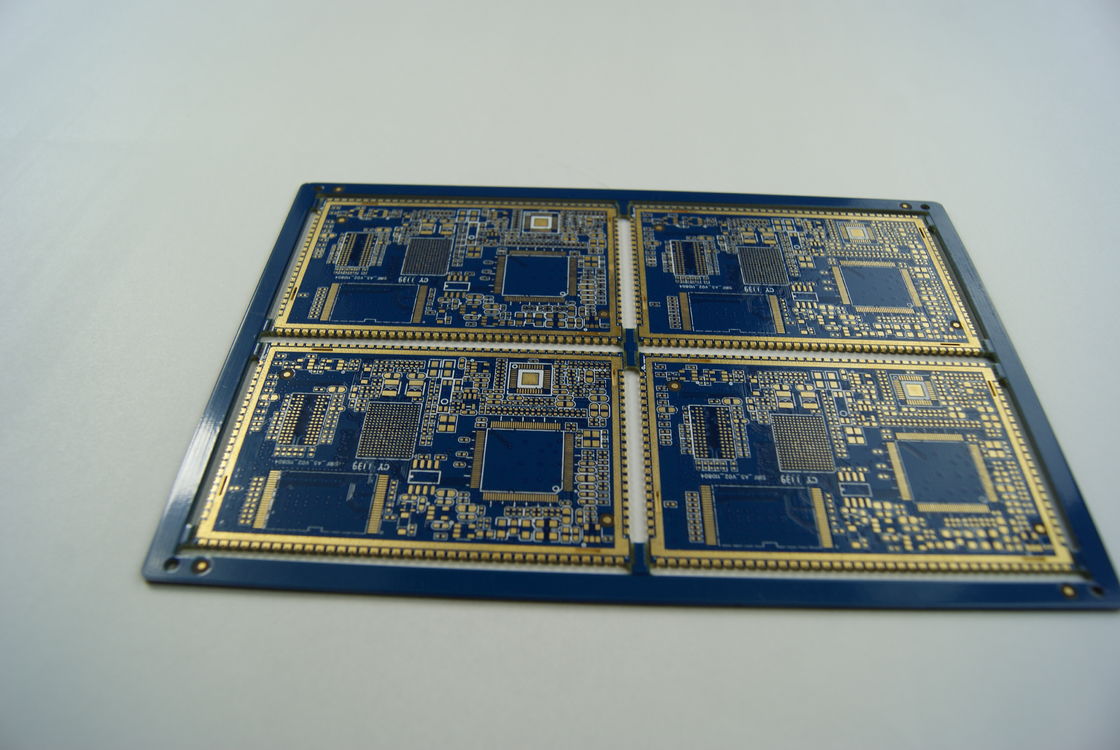

Immersion Silver Surface Multilayer PCB Board with Max. Big Size 600mm*1200mm

Product Description:

The Multilayer PCB Board represents a significant advancement in the electronic components industry, offering superior performance and functionality for a wide array of applications. At the core of modern electronics, these boards are designed to meet the stringent requirements of complex circuits and dense component layouts. Multilayer PCBs are widely utilized in various industries including telecommunications, medical devices, military equipment, and consumer electronics, due to their ability to provide high-quality signal transmission and durability in a compact form factor.

Our Multilayer PCB Board is constructed with precision engineering to ensure that each layer of the board is perfectly aligned and securely bonded. This meticulous construction process allows for the creation of a more complex circuitry on a single board, which is not possible with single-layer PCBs. The multilayer design also enhances the board's electrical properties by reducing electromagnetic interference (EMI), thereby improving signal integrity and power distribution.

Each Multilayer Printed Board is manufactured with a minimum hole size of 0.2mm. This fine detail allows for the inclusion of more components in a smaller space, which is crucial for the miniaturization of electronic devices. The holes are drilled with precision to ensure that components can be mounted accurately, which is essential for the board's reliability and function.

The copper thickness on our boards ranges from 0.5oz to 6oz, providing designers with the flexibility to choose the appropriate weight for their specific application. The copper weight is standardized at 12OZ, which guarantees a consistent quality across all boards. This consistency is critical for maintaining the performance of the board, especially when it comes to thermal management and current carrying capacity.

The overall thickness of the Multilayer PCB Board can vary from 0.2mm to 6.0mm. This range allows for adaptability in terms of board rigidity and space constraints within the device. Thinner boards are ideal for flexible applications, while thicker boards offer more support for heavier components. Regardless of the thickness, all boards are crafted to withstand the stresses of everyday use and the thermal cycling that occurs during the operation of electronic devices.

To ensure the highest level of protection during shipping and handling, each Multilayer PCB Board is packaged in vacuum packing with a carton box. This packaging method is specifically chosen to prevent moisture and environmental contaminants from compromising the board's quality. The vacuum seal safeguards the delicate components and copper surfaces from oxidation, while the sturdy carton box provides a robust shield against physical damage during transit.

Our Multilayer PCB Boards are not only designed for performance but also for ease of assembly. The precise manufacturing tolerances and high-quality materials used in the construction of the board ensure that it can be easily integrated into any electronic system. The boards are compatible with both through-hole and surface-mount technology (SMT), providing flexibility for various assembly processes.

In conclusion, our Multilayer PCB Board is a testament to our commitment to quality and innovation. With features that include a minimum hole size of 0.2mm, a copper thickness range of 0.5oz to 6oz, a standardized copper weight of 12OZ, and a thickness range of 0.2mm to 6.0mm, this board is poised to meet the demands of the most challenging electronic projects. The thoughtful packing in vacuum packing with a carton box ensures that the board arrives in pristine condition, ready for immediate use. Whether for high-speed digital applications, RF circuits, or high-power systems, our Multilayer Printed Board is the reliable choice for engineers and designers seeking the best in electronic component solutions.

Features:

- Product Name: Multilayer PCB Board

- Surface Finishes Available: HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, OSP

- Copper Weight: 12OZ

- Copper Thickness: 0.5oz-6oz

- Surface Mount Technology: Yes

- Max. Panel Size: 600mm*1200mm

- Also known as Multilayer PWB

- Capable of supporting 18 Layers PCBs construction

Technical Parameters:

| Parameter |

Specification |

| Copper Weight |

12OZ |

| Thickness |

0.2mm-6.0mm |

| Max. Panel Size |

600mm*1200mm |

| Number Of Layers |

4-32 Layers (including 12 Layers PCBs, 14 Layers PCBs, 18 Layers PCBs) |

| Copper Thickness |

0.5oz-6oz |

| Surface Mount Technology |

Yes |

| Special requirements |

Multiclass Impedance |

| Min. Hole Size |

0.2mm |

| Size |

/ |

| Service |

One-stop Service OEM |

Applications:

The Multilayer Printed Circuit Board (PCB) is a sophisticated and essential component in modern electronics, designed to accommodate complex and space-constrained circuitry. With a maximum panel size of 600mm*1200mm, these PCBs are ideal for a wide range of applications where large circuit designs are required. The thickness range of 0.2mm-6.0mm allows for flexibility in the design, accommodating various component heights and providing the necessary structural integrity for different uses.

Multilayer Circuitry Boards are commonly utilized in high-performance electronics where multiple circuits must coexist in close proximity. Industries such as aerospace, military, medical, and telecommunications frequently employ 10 Layers PCBs to meet their stringent requirements for reliability and performance under extreme conditions. The larger size and increased layer count facilitate complex routing and the inclusion of additional features such as RF shields and heat sinks.

Packaging for these PCBs includes vacuum packing with a carton box to ensure the boards are protected from moisture and physical damage during transit. This is especially important for boards with sensitive surface treatments. Speaking of surfaces, the Multilayer PCB Board comes with various finishing options including HASL (Hot Air Solder Leveling), Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, and OSP (Organic Solderability Preservatives). Each surface treatment offers different advantages in terms of solderability, conductivity, and shelf life, making them suitable for different application scenarios.

With Surface Mount Technology (SMT) compatibility, the Multilayer PCB Board is ready for the most advanced electronic components and assembly processes. SMT allows for smaller components to be mounted directly onto the PCB surface, resulting in more compact and efficient electronic devices. This technology is ideal for consumer electronics, automotive systems, and IoT devices where space is at a premium and functionality cannot be compromised.

In conclusion, the Multilayer PCB Board with a large panel size, varying thickness, and advanced surface treatment options, packed securely for delivery, is a versatile and high-quality choice for intricate electronic designs. Whether it's for a sophisticated aerospace navigation system, a critical medical device, or a cutting-edge telecommunications project, the Multilayer Circuitry Board stands as a pillar of modern electronics, supporting the complex functionalities demanded by today's technology-driven world.

Customization:

Our Multilayer PCB Board customization services cater to a wide range of product attributes to meet your specific requirements. We offer various surface finish options including HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, and OSP to ensure the reliability and longevity of your Multilayer PWB. With the availability of Surface Mount Technology, we can assemble components on the PCB with precision and efficiency.

For high-power applications, our PCBs can be customized with a substantial Copper Weight of up to 12OZ. Moreover, we provide a broad range of Copper Thickness options from 0.5oz to 6oz to accommodate different current-carrying capacities and thermal management needs. The overall Thickness of the PCB can also be tailored, ranging from a slim 0.2mm to a robust 6.0mm, ensuring that whether you are working with 12 Layers PCBs or 20 Layers PCBs, your product is built to your exact specifications.

Support and Services:

The Multilayer PCB Board comes with comprehensive technical support and services designed to assist you at every stage of the product lifecycle. Our team of expert engineers is available to provide guidance on design considerations, materials selection, and layout optimization to ensure your PCB meets the highest performance standards.

Our technical support also includes detailed documentation, such as datasheets and application notes, which provide valuable insights into the proper handling, integration, and maintenance of the Multilayer PCB Board. These resources are continually updated to reflect the latest industry practices and technological advancements.

In addition to support materials, we offer a suite of services to facilitate the smooth implementation of our PCBs into your projects. These services include prototype testing, where we validate the functionality and reliability of the PCB design, as well as thermal and signal integrity analysis to ensure your board performs optimally in its intended environment.

For those requiring production-level support, our services extend to include assembly assistance, where we guide you through the best processes for efficient and high-quality board assembly. We also provide troubleshooting assistance to quickly address and resolve any issues that may arise during the production or operation of the Multilayer PCB Board.

Our commitment to your success is unwavering, and we strive to provide exceptional service that extends beyond technical support. Continuous improvement and customer satisfaction are at the core of our support philosophy, ensuring that you receive the most effective and up-to-date assistance available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!