Immersion Gold Substrate PCBs with White Silkscreen 0.2mm ABF Material.

Product Description:

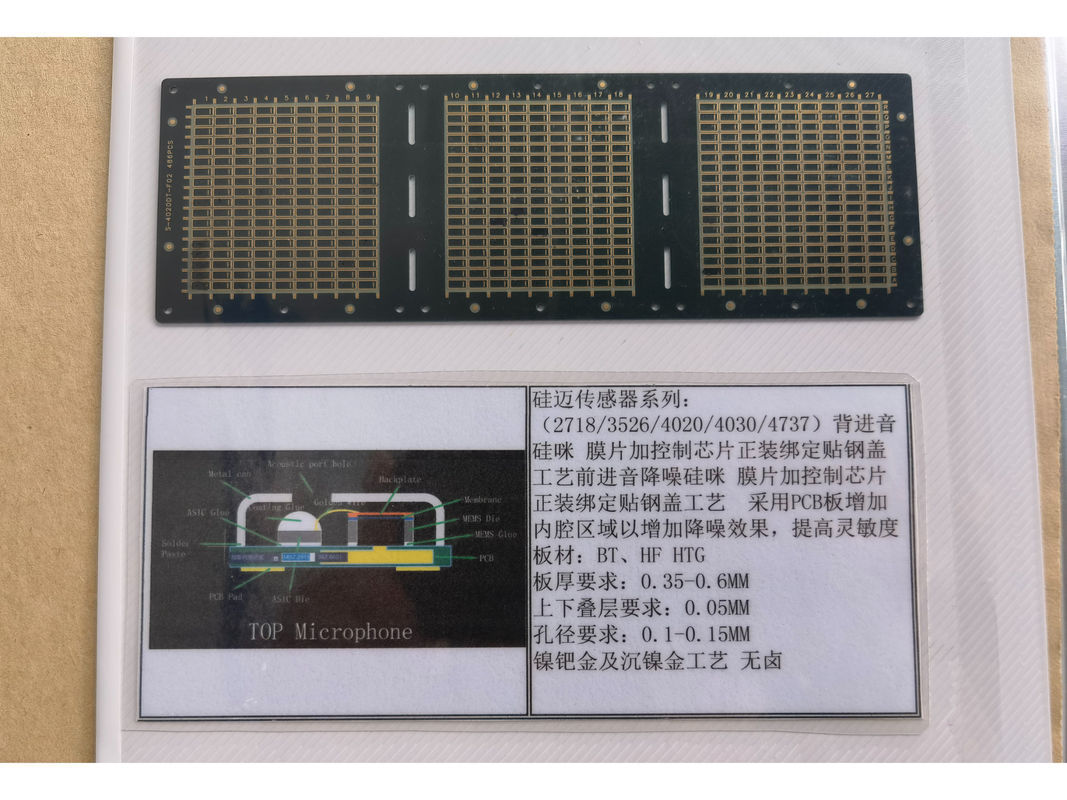

The world of electronics manufacturing is evolving with the advent of highly sophisticated and efficient circuit board designs. One of the most notable advancements in this field is the development of Substrate-Embedded Circuit Boards, which provide exceptional performance and reliability for a wide range of electronic devices. These PCBs with Substrate Layer are engineered to meet the stringent demands of modern electronic applications, offering a blend of precision, durability, and versatility.

Substrate-Type Printed Circuit Boards are a specialized form of PCB where the circuitry is integrated into a substrate material, providing a compact and highly efficient design. Our Substrate Like PCBs product is a prime example of this innovative approach, featuring a minimum trace width and spacing of just 0.1mm. This fine line technology allows for dense and complex circuits to be accommodated on a relatively small board, making them ideal for applications where space is at a premium and performance is critical.

Our Substrate Like PCBs are composed of two layers, which is a standard configuration that balances complexity with cost-effectiveness. This dual-layer structure allows for a sufficient level of interconnectivity for many standard electronic applications while maintaining a slim profile. The use of two layers also facilitates easier troubleshooting and repair compared to PCBs with a higher layer count, which can be more challenging to diagnose and service.

To ensure the highest level of quality and readability, our Substrate Like PCBs come with a white silkscreen color. The silkscreen layer is crucial as it contains the printed component designators, switch settings, test points, and other helpful markings that guide both assembly and subsequent maintenance. The contrast provided by the white silkscreen against the underlying substrate ensures that these important details are easily visible, reducing the risk of assembly errors and aiding in the efficient operation of the board.

Designed specifically for use in electronic devices, our Substrate Like PCBs find their application in a myriad of products ranging from consumer electronics to industrial control systems. The versatility of these PCBs makes them suitable for a wide spectrum of devices, including smartphones, tablets, laptops, medical equipment, and automotive electronics, to name just a few. The inherent design of these PCBs allows them to support complex circuit configurations, which are often necessary for the sophisticated functionality that modern electronic devices require.

The material used for our Substrate Like PCBs is ABF (Ajinomoto Build-up Film), which is known for its excellent electrical properties and its ability to enable fine-line circuitry. ABF material is chosen for its high performance and reliability, particularly in high-frequency applications. It supports the demands of advanced semiconductor packaging, making it an ideal substrate for our state-of-the-art PCBs. With the ABF material, our PCBs exhibit superior thermal stability and are better suited to withstand the rigors of intense electronic operations.

Our commitment to quality and innovation is evident in every aspect of our Substrate Like PCBs. From the precision of the 0.1mm trace width/spacing to the practicality of the white silkscreen, each feature is carefully considered to provide our customers with a product that not only meets but exceeds their expectations. Whether for consumer gadgets or sophisticated industrial machinery, our Substrate Like PCBs are the building blocks for reliable and high-performing electronic devices that stand the test of time.

Features:

- Product Name: Substrate Like PCBs

- Material: ABF

- Copper Weight: 1oz

- Min. Hole Size: 0.2mm

- Lead Time: 5-7 Days

- Application: Electronic Devices

- Category: Printed Circuit Boards

- Type: Substrate-based Circuit Boards

Technical Parameters:

| Attribute |

Details |

| Application |

Electronic Devices |

| Lead Time |

5-7 Days |

| Copper Weight |

1oz |

| Thickness |

0.2mm |

| Silkscreen Color |

White |

| Min. Hole Size |

0.2mm |

| Rohs Compliance |

Yes |

| Layers |

2 |

| Material |

ABF |

| Surface Finish |

Immersion Gold |

Applications:

Substrate Like PCBs (Printed Circuit Boards) are at the heart of modern electronic devices, providing the critical foundation for component mounting and signal routing. Featuring a surface finish of Immersion Gold, these PCBs offer excellent conductivity and resistance to oxidation, ensuring a reliable and long-lasting connection for components. The white silkscreen color provides a stark contrast for legible markings and identification, which is essential during both assembly and maintenance processes.

Designed with a minimum trace width and spacing of 0.1mm, these PCBs with Substrate Structure are capable of supporting high-density designs, which is a crucial requirement for today's compact and complex electronic devices. The precision in trace and spacing also allows for high-speed signal transmission, making them suitable for a variety of high-performance applications.

The lead time for these Substrate Like PCBs is set at 5-7 days, ensuring a quick turnaround for projects that are on a tight schedule. This efficient production time does not compromise the quality or performance of the PCBs, allowing designers and manufacturers to plan and execute their projects with confidence.

The application of PCBs with Substrate Structure spans a wide range of electronic devices. From consumer electronics like smartphones, tablets, and laptops to more specialized equipment such as medical devices, aerospace instrumentation, and automotive electronics, these PCBs provide the necessary platform for device functionality. The robust nature of the Immersion Gold surface finish and the precise trace width/spacing make them particularly suited for devices that require a high degree of reliability and performance.

In the realm of industrial electronics, these PCBs can be found in control systems, sensors, and automation technology. The white silkscreen aids in the clear marking of test points and component identifiers, which is critical for troubleshooting and repair in industrial settings. Additionally, the quick lead time means that production and prototype development can keep pace with the fast-moving advancements in industrial technology.

The versatility of Substrate Like PCBs also extends to telecommunications equipment, where signal integrity is paramount. The Immersion Gold finish provides a stable and low-resistance contact surface, ideal for the high-frequency signals that are typical in communication devices. The small trace width and spacing are conducive to the miniaturization trends in this sector, allowing for more complex circuitry in smaller form factors.

With their robust structure, precision, and rapid production time, Substrate Like PCBs are an essential component in the evolution and performance of a myriad of electronic devices. They embody the critical attributes that developers require to push the boundaries of technology and innovation.

Customization:

Our Substrate Like PCBs offer a robust solution for a variety of electronic devices. These Circuitry Boards with Substrate Components are designed to meet precise specifications. With a standard 2-layer configuration, they are ideal for complex electrical applications that require reliable performance.

The Substrate Like PCBs feature a minimum hole size of 0.2mm, which allows for precise component placement and high-density interconnections. Our advanced manufacturing processes ensure that each board meets the highest quality standards.

Additionally, the minimum trace width and spacing on these boards are set at 0.1mm. This fine detail enables the accommodation of a high number of traces, ensuring efficient signal transmission and reducing the risk of short-circuiting.

With a copper weight of 1oz, our Substrate Like PCBs provide excellent conductivity and thermal management, which are essential for maintaining the integrity of your electronic devices under varying operational conditions.

Support and Services:

Our Substrate Like PCB (SLP) products come with comprehensive technical support and services designed to ensure your success in utilizing our advanced circuit board technology. This support includes access to a range of resources and services aimed at optimizing the performance, reliability, and integration of our SLPs into your projects.

Our services include detailed product documentation, which provides essential information and guidelines for the design, handling, and implementation of our PCBs. We also offer design review services to help ensure that your SLP designs are optimized for manufacturability and performance.

For technical issues or challenges, our team of expert engineers is available to provide troubleshooting assistance and advice. We are committed to resolving any technical concerns swiftly to minimize any impact on your production schedules.

In addition to reactive support, we provide proactive technical consulting to help you anticipate and prevent potential issues before they arise. Our goal is to help you maintain a seamless production process and get the most out of our advanced SLP technology.

We continuously work on improving our products and services, and welcome feedback from our customers. By staying at the forefront of PCB technology, we ensure that our Substrate Like PCB solutions meet the evolving needs of the electronics industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!