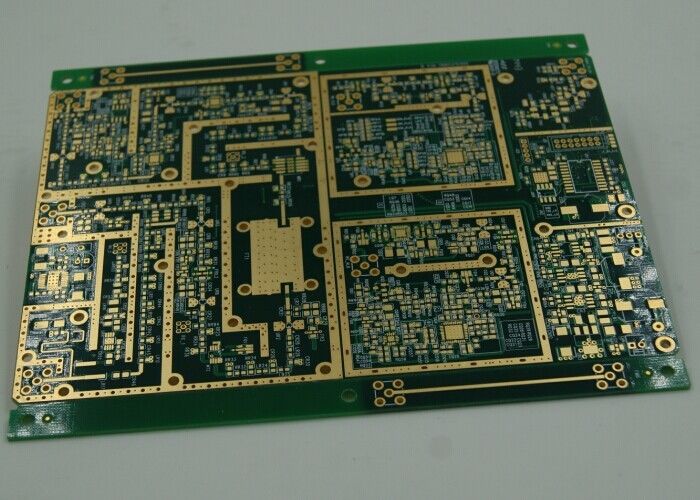

High speed material TU-933 FR-4 Glass Epoxy DK 3.6 Multilayer PCB Board 4-22 Layers

Product Description:

The Multilayer PCB Board is a cutting-edge solution for sophisticated electronic applications that demand high performance, durability, and compact design. This product is skillfully engineered to cater to a broad range of industries, from consumer electronics to aerospace, medical to military, and beyond. The Multilayer PCB Board is available in configurations from 4 to 22 layers, offering immense versatility and adaptability to various complex circuit designs.

At the heart of the Multilayer PCB Board is its multilayer circuit board technology. Each board is meticulously constructed with multiple layers of conductive material and insulating substrates, all bonded together under heat and pressure to form a single, integrated unit. This multi-tiered approach provides several advantages over traditional single or double-layer PCBs, including increased circuit density, improved signal integrity, and enhanced electrical performance.

One of the most critical aspects of the Multilayer PCB Board is its minimum hole size of 0.2mm. This feature allows for high-density interconnects (HDI), enabling designers to place more components on the board and reduce the overall size of the product. Smaller via sizes lead to better electrical performance and allow for the use of finer pitch components, which is essential in modern electronic devices that necessitate increased functionality within limited spaces.

The Multilayer PCB Board is also equipped with Surface Mount Technology (SMT), which is a must-have for contemporary PCB manufacturing. SMT allows for automated assembly processes that place components directly onto the surface of the board, as opposed to through-hole technology that requires leads to be inserted into drilled holes. This technology facilitates faster production times, greater space efficiency, and enhanced reliability, making it an ideal choice for high-volume production runs.

One of the standout materials used in the production of the Multilayer PCB Board is the Rogers PCB Board substrate. Rogers material is known for its superior electrical properties, such as a stable dielectric constant and low loss, which are critical in high-frequency applications. This makes it an excellent choice for designs that require minimal signal loss, such as RF and microwave circuits. By integrating Rogers material into multilayer PCBs, the product delivers consistent performance even in the most demanding environments.

The 16 Layers PCBs are a prime example of the capabilities of the Multilayer PCB Board. With 16 separate layers of circuitry, these PCBs offer an exceptional balance of complexity and performance. They provide ample space for routing and power distribution while maintaining a compact form factor. The 16 Layers PCBs are particularly suited for advanced computing, telecommunications, and industrial applications where multiple signals and power levels must be managed simultaneously.

In summary, the Multilayer PCB Board represents the pinnacle of PCB design and manufacturing. Its scalability from 4 to 22 layers caters to a wide array of requirements, ensuring that even the most complex electronic systems can be accommodated. The commitment to precision, with a minimum hole size of 0.2mm, and the adoption of Surface Mount Technology, transform these boards into highly efficient and reliable platforms for a multitude of applications. Furthermore, the incorporation of the Rogers PCB Board material provides a robust foundation for high-frequency performance. For designers and engineers seeking a Multilayer PCB that embodies quality, innovation, and versatility, this Multilayer PCB Board is the definitive choice for pushing the boundaries of electronic design.

Features:

- Product Name: Multilayer PCB Board

- Glass Epoxy: RO4003C+ Tg170 FR-4

- Packing: Vacuum Packing With Carton Box

- Copper Weight: 12OZ

- Key Word: Rogers PCB Board

- Copper Thickness: 0.5oz-6oz

- Number of Layers: 14 Layers PCBs

- Type: Multilayer PCB

Technical Parameters:

| Attribute |

Details |

| Max. Panel Size |

600mm*1200mm |

| Packing |

Vacuum Packing With Carton Box |

| Thickness |

0.2mm-6.0mm |

| Min. Hole Size |

0.2mm |

| Key Word |

Rogers PCB Board |

| Surface Mount Technology |

Yes |

| Copper Weight |

12OZ |

| Size |

/ |

| Layers |

4-22 Layer |

| Surface |

HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, OSP |

Applications:

The Multilayer PCB Board, boasting a substantial copper weight of 12OZ, is a paramount choice for applications that demand high power and durability. Crafted from the robust combination of RO4003C Glass Epoxy and Tg170 FR-4 materials, this board ensures consistent performance even under extreme thermal stress. The versatility of copper thickness ranging from 0.5oz to 6oz makes this Multilayer Circuit Board adaptable to various electrical requirements. With the capability to handle complex circuits, it is an ideal substrate for developing 14 Layers PCBs.

One of the primary application occasions for such a sturdy Multilayer PCB Board is in industrial-grade power electronics. Devices such as high-power rectifiers, voltage regulators, and converters benefit immensely from the board’s capacity to manage heavy current loads without compromising on performance or safety. The thermal management properties of the Glass Epoxy and FR-4 materials are particularly beneficial in environments where the board is exposed to high operating temperatures over prolonged periods.

In the field of telecommunications, the need for reliable and efficient signal transmission paves the way for the use of 14 Layers PCBs. These multilayer boards provide the necessary platform for dense circuit designs that are typical in communication satellites, base stations, and networking switches. The high copper weight ensures minimal signal loss, while the precision of our one-stop service OEM offering guarantees that each board is tailored to the exact specifications required by the client.

The Multilayer Circuit Board also finds its significance in the realm of medical equipment manufacturing. High-end devices such as MRI machines, CT scanners, and ultrasonic equipment rely on multilayer PCBs to perform critical tasks with precision and reliability. The OEM service ensures that every board complies with the stringent standards of the medical industry, providing confidence in the performance and safety of these life-saving machines.

Moreover, in the aerospace sector, the robustness of the Multilayer PCB Board is put to the test. Aerospace applications demand components that can withstand the rigors of space and flight, including exposure to radiation, extreme vibrations, and drastic temperature changes. 14 Layers PCBs made with our high-quality materials provide the necessary resilience and longevity for spacecraft, satellites, and avionics systems.

To sum up, the Multilayer PCB Board with its high copper weight, versatile thickness options, and superior materials, is an essential component in industries where reliability, performance, and precision are non-negotiable. Whether it is through our one-stop service OEM for custom designs or standard 14 Layers PCBs, this product is poised to meet the rigorous demands of power electronics, telecommunications, medical devices, and aerospace applications.

Customization:

Our Multilayer PCB Board customization services cater to a diverse range of layer counts, offering options from 4-22 Layer boards. We specialize in fabricating high-density 18 Layers PCBs , 12 Layers PCBs , and 14 Layers PCBs , ensuring that your project's requirements are met with precision.

We provide a comprehensive One-stop Service OEM experience, streamlining the production process from design to final assembly. Our boards are built to last, featuring a substantial 12OZ Copper Weight for improved conductivity and thermal management.

Incorporating high-quality Glass Epoxy RO4003C+ Tg170 FR-4 materials, our PCBs are designed for superior performance and durability under demanding conditions.

We also support intricate designs with our capability to drill Min. Hole Size as small as 0.2mm , allowing for complex routing and connectivity in your electronic applications.

Support and Services:

At our company, we are dedicated to ensuring your complete satisfaction with our Multilayer PCB Board products. Our comprehensive product technical support and services are designed to address any concerns or questions you might have, ensuring that your experience with our products is seamless and satisfactory.

Our technical support includes:

- Product Installation Guidance: Step-by-step assistance with the installation of your Multilayer PCB Board, ensuring proper setup for optimal performance.

- Troubleshooting Assistance: Swift and effective help in diagnosing and resolving any issues you may encounter during the operation of your PCB board.

- Firmware Updates: Access to the latest firmware updates to improve functionality and security of your PCB board.

- Technical Documentation: Comprehensive manuals, datasheets, and application notes to provide you with detailed information about your Multilayer PCB Board.

In addition to technical support, we offer a variety of services to enhance your experience:

- Warranty Service: Our Multilayer PCB Boards come with a standard warranty, covering any manufacturing defects and ensuring peace of mind with your purchase.

- Advanced Replacement Service: In the unlikely event of a product failure, we offer an advanced replacement service to minimize any disruption to your operations.

- Product Training: Customizable training sessions to help you and your team understand and utilize your Multilayer PCB Board to its fullest potential.

- Customer Feedback Program: We value your input and encourage you to participate in our feedback program to help us continuously improve our products and services.

We are committed to providing you with the highest level of support and service. Our goal is to ensure that your Multilayer PCB Board meets your needs and exceeds your expectations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!