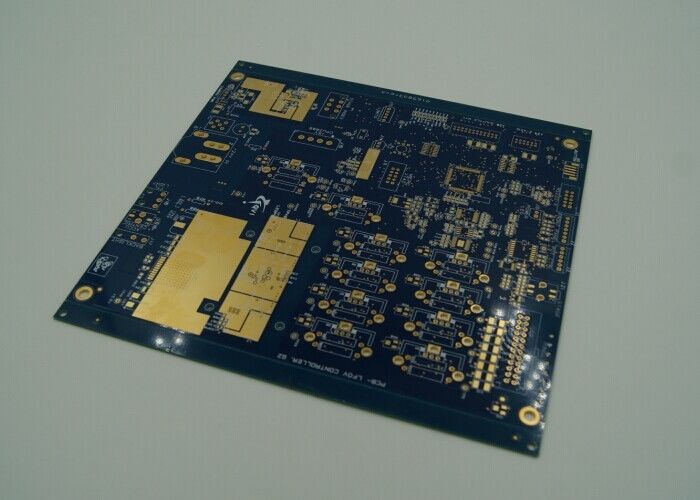

Advanced Multilayer PCB Board Panasonic M6 M8 FR-4 4-22 Layers High speed PCB prototype

Product Description:

The Multilayer PCB Board is a technological marvel tailored to meet the rigorous demands of the modern electronics industry. Constructed with the utmost precision, this product stands as a testament to the advancements in circuit board technology. At its core, the board is composed of high-quality Glass Epoxy: RO4003C+ Tg170 FR-4 material, ensuring a robust and reliable foundation for a multitude of electronic applications.

With a versatile range of 4-22 layers, customers can select the perfect Multilayer PCB Board configuration to suit their specific requirements. This level of customization is particularly beneficial for projects that necessitate additional complexity, such as 10 Layers PCBs, which are often sought after for their enhanced performance and space-saving design. By integrating multiple layers into a single board, these PCBs provide a compact and efficient solution for high-density circuit designs.

The adoption of Surface Mount Technology (SMT) in the manufacturing process is a significant feature of these boards. This modern technique allows for the direct mounting of components onto the surface of the PCB, resulting in a more streamlined and reliable circuit. The integration of SMT not only improves the overall quality and performance of the Multilayer Printed Board but also expedites the assembly process, leading to faster production times and reduced costs.

One of the key attributes of this exceptional product is the One-stop Service OEM offering. This service ensures that clients receive comprehensive support throughout the design, manufacturing, and assembly stages. The convenience of an OEM service means that customers can rely on a single source for all their PCB needs, from initial concept to final product delivery. This streamlined approach not only simplifies the procurement process but also ensures that each Multilayer PCB Board meets the highest standards of quality and consistency.

The Multilayer PCB Board is engineered with a significant Copper Weight of 12OZ. This substantial copper thickness is instrumental in enhancing the current carrying capacity of the board, which is crucial for high-power applications. The increased copper weight also helps in dissipating heat more efficiently, thereby improving the thermal management of the board and extending the life of the electronic components.

Attention to detail is evident in every aspect of the Multilayer Printed Board's design. The use of Glass Epoxy: RO4003C+ Tg170 FR-4 material not only provides high mechanical strength but also ensures excellent thermal stability and electrical insulation. These properties are crucial for maintaining the integrity of the board under varying environmental conditions and during the thermal cycles of operation. The high glass transition temperature (Tg) of 170 degrees Celsius further signifies the board's ability to withstand high temperatures without compromising its structural or functional integrity.

In conclusion, the Multilayer PCB Board embodies the cutting-edge of PCB design and manufacturing. With its robust Glass Epoxy construction, the versatility of 4-22 layers, the precision of Surface Mount Technology, the comprehensive One-stop Service OEM, and the substantial 12OZ Copper Weight, this product is poised to meet the diverse and demanding needs of the electronics industry. Whether it's for simple devices or complex 10 Layers PCBs, the Multilayer Printed Board is the ideal choice for those seeking quality, performance, and reliability in their electronic endeavors.

Features:

- Product Name: Multilayer PCB Board

- Copper Thickness: 0.5oz-6oz

- Max. Panel Size: 600mm*1200mm

- Surface Mount Technology: Yes

- Glass Epoxy: RO4003C+ Tg170 FR-4

- Key Feature: Multilayer Circuit Board

- Key Feature: Multilayer PWB (Printed Wiring Board)

- Key Feature: 18 Layers PCBs

Technical Parameters:

| Parameter |

Specification |

| Surface |

HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, OSP |

| Max. Panel Size |

600mm*1200mm |

| Size |

/ |

| Surface Mount Technology |

Yes |

| Thickness |

0.2mm-6.0mm |

| Min. Hole Size |

0.2mm |

| Key Word |

Rogers PCB Board |

| Packing |

Vacuum Packing With Carton Box |

| Layers |

4-22 Layer |

| Copper Weight |

12OZ |

Applications:

The Multilayer PCB, an essential component in the world of electronics, is a highly versatile and advanced type of printed circuit board (PCB) that has become an industry standard for complex circuitry. With a range of thicknesses from 0.2mm to 6.0mm and the capability to have anywhere from 4 to 22 layers, these PCBs are engineered to provide high functionality in a compact form. The Multilayer PWB (Printed Wiring Board) design allows for a greater density of electrical paths, components, and connections, making it an ideal solution for sophisticated electronic applications.

16 Layers PCBs represent a complex tier of Multilayer PCBs, catering to applications where space and functionality are at a premium. The layer count enables a high degree of interconnectivity and the ability to manage multiple signals and power planes efficiently. The copper thickness in these boards can vary between 0.5oz to 6oz, allowing for improved current carrying capacity and enhanced thermal management. This makes 16 layer PCBs particularly suited for high-speed and high-frequency circuitry found in telecommunications equipment, advanced computing systems, and military-grade electronics.

The application occasions and scenarios for these Multilayer PCBs are numerous. Due to their enhanced capabilities, they are often found in medical devices such as MRI systems and heart monitors, where reliability and precision are paramount. In the aerospace industry, the compact size and robustness of Multilayer PWBs make them perfect for space-constrained avionics and satellite systems. The automotive industry, with its increasing reliance on electronics for safety, performance, and comfort features, also benefits from the use of sophisticated Multilayer PCBs for control systems, GPS navigation, and infotainment systems.

Moreover, consumer electronics such as smartphones, tablets, and laptops continually push the boundaries for thinner, more powerful devices. Multilayer PCBs are at the heart of these innovations, enabling the integration of multiple functions within limited spaces. The 4-22 layer boards are equally important in industrial applications, where they are utilized in complex machinery and automation systems requiring reliable and long-lasting electronic components.

In conclusion, the versatility and advanced capabilities of Multilayer PCBs, especially the intricate 16 Layers PCBs, make them an integral part of electronic designs across a wide array of industries. Their ability to accommodate a high layer count with varying copper thicknesses while maintaining a small footprint allows for cutting-edge developments in technology and contributes to the advancement of a multitude of electronic products.

Customization:

We offer comprehensive Product Customization Services for our Multilayer PCB Board, which is available from 4 to 22 layers. Our advanced manufacturing capabilities allow us to produce a wide range of specifications, including high-density 20 Layers PCBs and standard 14 Layers PCBs. The surface finish options we provide are extensive, catering to your specific needs: HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, and OSP.

Although the size of the Multilayer PCB can vary, we ensure precision and quality across all dimensions. When it comes to copper thickness, our customers can select from 0.5oz up to a robust 6oz to meet the electrical requirements of their applications. Additionally, our Multilayer PCBs are fully compatible with Surface Mount Technology (SMT), ensuring reliable and efficient assembly for all your circuitry needs.

Support and Services:

Our Multilayer PCB Board comes with comprehensive technical support and services designed to ensure the best possible experience with our product. Our support includes access to a knowledge base with extensive documentation, troubleshooting guides, and detailed technical specifications to help you understand and utilize your PCB effectively.

In addition to our online resources, we offer a variety of services to assist you with the implementation and maintenance of your Multilayer PCB Board. These services include design review and consultation, to ensure that your PCB design is optimized for manufacturing and functionality.

To help you maintain the performance and reliability of your PCBs, we also provide rework and repair services. Our team of experts can help diagnose issues and perform necessary repairs or suggest improvements to avoid future problems.

We are committed to providing ongoing support and updates for our products. This includes providing information on the latest industry standards and technologies, as well as updates to our own product offerings.

Our goal is to provide exceptional support and services to our customers, helping to ensure the success of their projects and the long-term performance of their Multilayer PCB Boards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!