Product Description:

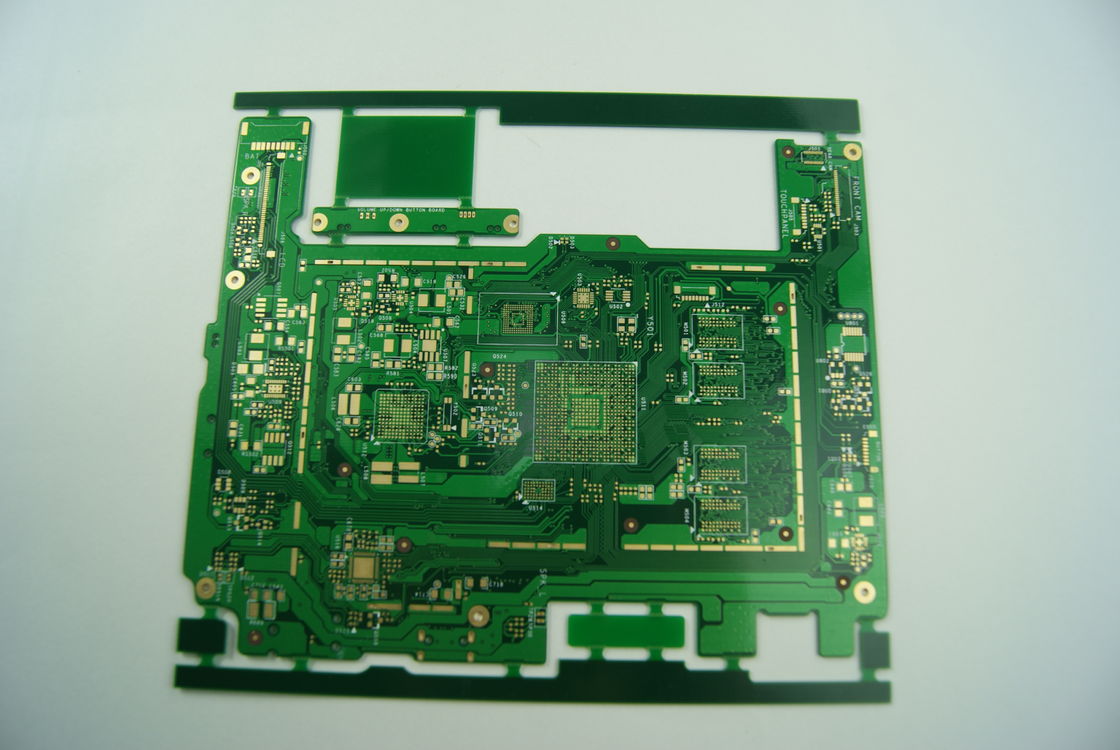

The Multilayer PCB Board is a fundamental component in modern electronics, providing the structure and connectivity for a multitude of electrical components and systems. Designed to cater to advanced technological needs, these PCBs are constructed with precision and tailored to serve a wide range of applications, from consumer electronics to sophisticated aerospace instrumentation.

One of the critical attributes of our Multilayer PCB Board is the minimum hole size of 0.2mm. This allows for high-density interconnection, ensuring that even the most complex circuits can be accommodated on a single board. This capability is particularly crucial in designs such as 18 Layers PCBs and 14 Layers PCBs, where space optimization and electrical performance are of paramount importance.

The material used in the construction of these PCBs is Glass Epoxy: RO4003C+ Tg170 FR-4. This composite material is known for its excellent thermal resistance, mechanical durability, and electrical insulation properties. The Tg170 rating indicates a high glass transition temperature, which means the PCB can sustain higher temperatures before it begins to deform. This property is essential for reliability and longevity, especially in devices that operate under high-temperature conditions.

The thickness of the Multilayer PCB Board can range from 0.2mm to 6.0mm. This variation in thickness provides a versatile platform for accommodating different component sizes and weights, ensuring that whether you are working with delicate, lightweight components or robust, heavy parts, the PCB will offer adequate support and connectivity.

Surface finishes are crucial for protecting the copper on the surface of the PCB and to ensure solderability. Our boards come with a variety of surface finish options, including HASL (Hot Air Solder Leveling), Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, and OSP (Organic Solderability Preservatives). Each of these finishes has unique benefits, such as enhancing the solderability of the board, preventing oxidation, and providing a robust interface for component mounting. The selection of surface finish will depend on the specific requirements of the application in terms of durability, conductivity, and assembly processes.

Our Multilayer PCB Board is also characterized by a copper thickness ranging from 0.5oz to 6oz. This range of copper thickness options allows for the adjustment of the board's current-carrying capacity, impedance, and thermal distribution. Thicker copper layers are beneficial in high-power applications where increased current flow is necessary, while thinner layers are suitable for more delicate, precision-driven operations.

The ability of our PCBs to integrate multiple layers, such as in 18 Layers PCBs or 14 Layers PCBs, translates to a heightened level of complexity and functionality within a compact space. This multilayer construction enables the creation of more extensive networks of wiring without expanding the board's footprint. It is an essential feature for modern electronic devices, which demand miniaturization without compromising on performance.

In conclusion, the Multilayer PCB Board is a highly adaptable and robust platform that is indispensable in the electronics industry. With features like a min. hole size of 0.2mm, Glass Epoxy RO4003C+ Tg170 FR-4, a thickness range of 0.2mm-6.0mm, various surface finishes, and copper thickness options of 0.5oz-6oz, this PCB is designed to meet the most demanding requirements. Whether it's for high-layer-count applications such as 18 Layers PCBs or 14 Layers PCBs or for other complex electronic assemblies, our Multilayer PCB Boards ensure reliability, performance, and efficiency.

Features:

- Product Name: Multilayer PCB Board

- Key Word: Rogers PCB Board

- Min. Hole Size: 0.2mm

- Max. Panel Size: 600mm*1200mm

- Surface Mount Technology: Yes

- Layers: 4-22 Layer

- Feature: 14 Layers PCBs

- Feature: Multilayer Printed Circuit Board

- Feature: 18 Layers PCBs

Technical Parameters:

| Attribute |

Specification |

| Surface |

HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, OSP |

| Glass Epoxy |

RO4003C+ Tg170 FR-4 |

| Layers |

4-22 Layer |

| Min. Hole Size |

0.2mm |

| Packing |

Vacuum Packing With Carton Box |

| Thickness |

0.2mm-6.0mm |

| Size |

/ |

| Max. Panel Size |

600mm*1200mm |

| Surface Mount Technology |

Yes |

| Key Word |

Rogers PCB Board |

Applications:

The Multilayer PCB Board, equipped with a substantial copper weight of 12OZ, is designed for high-power and high-current applications. The robust copper weight ensures that the PCB can handle increased power without risking damage or overheating, making it ideal for industrial power converters, high-end amplifiers, and automotive power supplies. The ability to manage more considerable power densities makes the Multilayer PWB suitable for occasions where reliability and durability are paramount.

With the integration of Surface Mount Technology (SMT), the Multilayer PCB Board is poised for scenarios requiring high-density component placement. This technology enables the board to support more components per unit area, facilitating compact and efficient designs. Consequently, it is perfectly suited for sophisticated electronic devices such as smartphones, tablets, and laptops, where space is at a premium and the complexity of the circuit is high. SMT on the Multilayer PCB Board also allows for automated manufacturing, ensuring high precision and quality for mass-produced electronic goods.

Offering a varied range from 4 to 22 layers, these Multilayer PCB Boards can be customized for a wide array of applications. The 14 Layers PCBs, in particular, provide an excellent balance between complexity and manageability, making them a go-to for advanced communication systems, military electronics, and medical monitoring devices. The multiple layers enable designers to create more intricate circuits, providing enhanced functionality and better signal integrity for critical applications.

With a minimum hole size of 0.2mm, the Multilayer PCB Board supports the inclusion of fine-pitch components, which is crucial for modern electronic devices that require dense component configurations. This feature is particularly beneficial for high-speed signal applications, such as servers, GPS technology, and satellite systems, where precision is critical for performance.

The packaging of the Multilayer PWB also reflects its intended use in professional and commercial settings. Vacuum packing with a carton box is the standard, ensuring that the boards are protected from moisture, dust, and static during transportation and storage. This packaging method is ideal for electronics manufacturers and assemblers who require their components to be delivered in pristine condition, ready for immediate use in sensitive equipment assembly lines.

In summary, the Multilayer PCB Board with its robust copper weight, Surface Mount Technology, customizable number of layers, and precise minimum hole size, is an indispensable component in a myriad of applications that require high performance, reliability, and precision. Whether it is for consumer electronics, industrial systems, or critical communication infrastructure, the Multilayer PCB Board stands as a testament to modern engineering and technological advancement.

Customization:

Our One-stop Service OEM offers comprehensive Product Customization Services for Multilayer PCB Board products. Tailor your PCBs to meet specific requirements, whether you need advanced 14 Layers PCBs or standard 10 Layers PCBs . We utilize high-quality materials such as RO4003C+ Tg170 FR-4 Glass Epoxy to ensure durability and performance.

While the size is customizable to your needs, our surface finish options are extensive, including HASL, Immersion Gold, Immersion Tin, Immersion Silver, Gold Finger, and OSP to enhance the solderability and reliability of your Multilayer Printed Board . Additionally, we provide state-of-the-art Surface Mount Technology (SMT) services, ensuring that your PCBs are equipped for modern electronic component assembly.

Support and Services:

Our Multilayer PCB Board is designed with precision and quality to meet the high demands of various industries. To ensure the best performance and longevity of your product, we offer comprehensive technical support and services. Our dedicated team of experts is available to assist with any technical inquiries you may have regarding installation, operation, or troubleshooting of your Multilayer PCB Board.

We provide detailed documentation, including a user manual and technical specifications, to facilitate a smooth setup process. Additionally, our online resources include FAQs, instructional videos, and application notes that are continuously updated to help you understand the full capabilities of your Multilayer PCB Board.

For more complex issues or personalized assistance, our support team can provide guidance through a step-by-step resolution process. We are committed to ensuring that your experience with our Multilayer PCB Board is efficient, reliable, and satisfactory.

Our services also include regular firmware updates to keep your Multilayer PCB Board up to date with the latest improvements and security patches. We strive to continually enhance our products and services to exceed industry standards and customer expectations.

Please note that our technical support and services are available during standard business hours and may be subject to our service terms and conditions. We encourage you to contact us for any support needs you have regarding your Multilayer PCB Board, and we will endeavor to provide a timely and effective solution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!