Product Description:

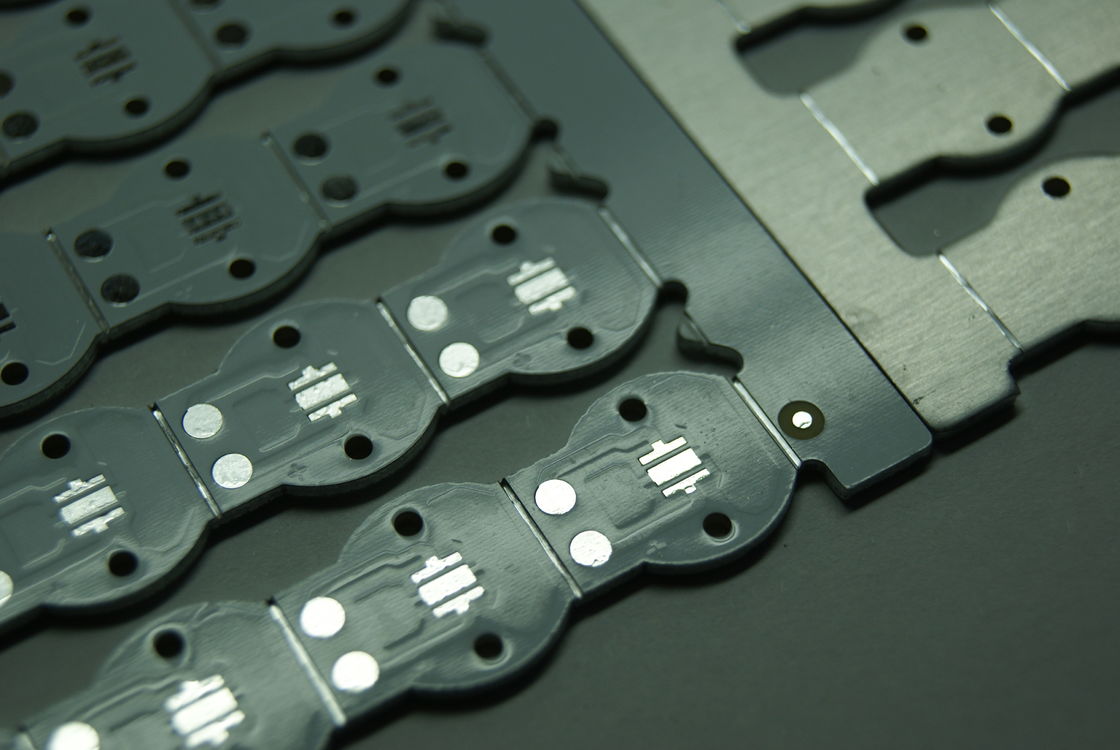

IMS PCB, short for Insulated Metal Substrate PCB, is a type of printed circuit board that offers excellent thermal management capabilities, making it ideal for applications requiring efficient heat dissipation. The IMS PCB product line offers a range of specifications to meet various project requirements.

Key Attributes:

- Layers: 2-16

- Surface Finish: HASL, ENIG, OSP

- Tensile Strength: Excellent, >300Mpa, 1.2~1.6N/mm

- Type: Copper Clad Laminate

- Silkscreen Color: White, Black, Yellow

IMS PCBs are widely used in industries such as automotive, LED lighting, power supplies, and telecommunications due to their efficient thermal properties and reliable performance. The IMS PCB product line encompasses various options to cater to different project specifications.

With a layer count ranging from 2 to 16, IMS PCBs offer flexibility in design and functionality, accommodating projects of varying complexities. Whether you require a simple double-layer IMS PCB or a more intricate multilayer design, the IMS PCB product line has you covered.

The surface finish options of HASL, ENIG, and OSP provide versatility in terms of solderability and corrosion resistance, ensuring the durability and longevity of the PCBs. Whether you prioritize cost-effectiveness, RoHS compliance, or high reliability, the IMS PCB product line offers suitable surface finish options to meet your specific requirements.

When it comes to tensile strength, IMS PCBs excel with a rating of over 300Mpa and a range of 1.2 to 1.6N/mm. This robust tensile strength ensures the mechanical integrity of the PCB, making it suitable for applications that require durability and resistance to environmental stressors.

As a type of Copper Clad Laminate, IMS PCBs combine the thermal conductivity of metal with the electrical insulation properties of laminate, creating a highly efficient and reliable PCB solution. The Copper Clad Laminate construction of IMS PCBs makes them well-suited for applications where thermal management is crucial.

Furthermore, the availability of silkscreen colors in White, Black, and Yellow adds a customization element to the IMS PCB product line, allowing for easy identification, branding, and aesthetic appeal in various applications. The choice of silkscreen colors enhances the visual presentation of the PCBs while also serving practical purposes.

In summary, IMS PCBs offer a comprehensive range of features and options to cater to diverse project requirements. Whether you are looking for a ventec metal PCB, Begquist metal Core PCB, or Polytronics PCBs, the IMS PCB product line provides reliable solutions for thermal management, durability, and performance in a variety of industries.

Features:

-

Product Name: IMS PCB

-

Withstand Voltage: >3KV

-

Silkscreen Color: White, Black, Yellow

-

Material: FR-4

-

Min. Silkscreen Bridge: 0.1mm

-

Tensile Strength: Excellent, >300Mpa, 1.2~1.6N/mm

Technical Parameters:

|

Type

|

Copper Clad Laminate

|

|

Surface Finish

|

HASL, ENIG, OSP

|

|

Withstand Voltage

|

>3KV

|

|

Service

|

PCB Fabrication

|

|

Silkscreen Color

|

White, Black, Yellow

|

|

Tensile Strength

|

Excellent, >300Mpa, 1.2~1.6N/mm

|

|

Impedance Control

|

Yes

|

|

Solder Mask Color

|

Green, Red, Blue, Black

|

|

Silkscreen

|

White, Black, Yellow

|

|

Material

|

FR-4

|

Applications:

The IMS PCB product is a type of Copper Clad Laminate made from FR-4 material, known for its excellent tensile strength of over 300Mpa and 1.2~1.6N/mm. The PCB comes with silkscreen color options in White, Black, and Yellow, making it versatile for various applications.

The high thermal conductivity metal PCB is ideal for scenarios where heat dissipation is crucial. Its excellent thermal management properties make it suitable for use in high-power LED lighting, automotive electronics, power supplies, and industrial control systems. The IMS PCB's ability to efficiently transfer heat away from components helps in maintaining optimal operating temperatures and prolonging the lifespan of electronic devices.

For applications requiring enhanced thermal performance, the Begquist metal Core PCB variant of IMS PCB is a preferred choice. It is commonly used in telecommunications equipment, medical devices, and aerospace technology, where thermal stability is paramount for reliable operation. The Begquist metal Core PCB ensures efficient heat dissipation, reducing the risk of overheating and improving overall system performance.

Additionally, the PTTC metal PCB version of IMS PCB is suitable for scenarios demanding high reliability and precision. Its stable thermal properties make it ideal for use in military electronics, aerospace systems, and high-precision instrumentation. The PTTC metal PCB's ability to maintain consistent thermal conductivity ensures the reliable operation of sensitive components under challenging environmental conditions.

With customizable layer options ranging from 2 to 16 layers, the IMS PCB product caters to a wide range of design requirements. Whether for prototyping or mass production, the flexibility in layer configurations allows for the creation of complex and compact electronic designs while ensuring efficient heat dissipation and reliable performance.

Customization:

Product Customization Services for the IMS PCB product:

Base Material: Aluminum Base, CUSTOM

Surface Finish: HASL, ENIG, OSP

Layers: 2-16

Material: FR-4

Surface Finishing: OSP/ ENIG/ Im Ag/ HASL/ Golden Finger

Support and Services:

Our Product Technical Support and Services for the IMS PCB product aim to provide comprehensive assistance to our customers. Our team of experienced technicians and engineers are dedicated to helping you with any technical issues or questions you may have regarding the IMS PCB product.

We offer a range of services, including product troubleshooting, installation support, and maintenance guidance. Our goal is to ensure that you have a seamless experience with our IMS PCB product and that any technical issues are resolved promptly and efficiently.

For further assistance or to inquire about our technical support services, please do not hesitate to reach out to our dedicated support team. We are committed to providing you with the support you need to maximize the performance and reliability of your IMS PCB product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!