Product Description:

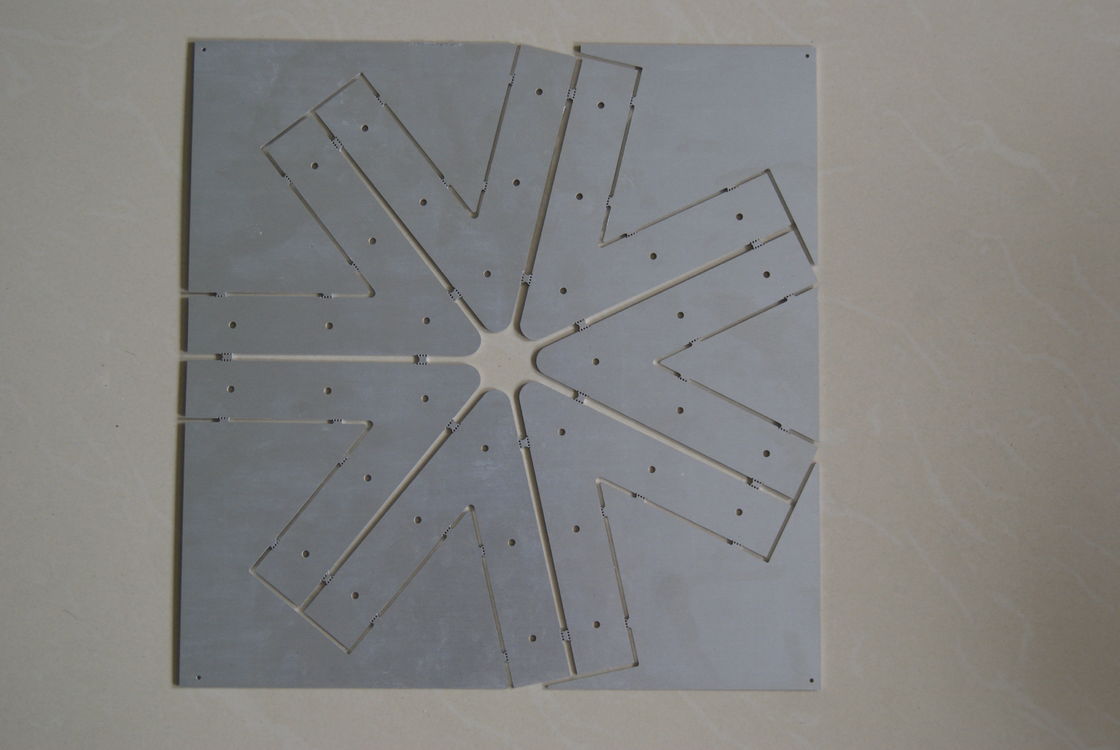

IMS PCB, also known as Insulated Metal Substrate PCB, is a specialized type of printed circuit board that offers unique features and benefits, making it ideal for various applications. This product summary will provide an in-depth overview of the IMS PCB product, highlighting its key attributes and advantages.

Silkscreen: The IMS PCB is available with silkscreen options in White, Black, and Yellow colors, allowing for clear and precise labeling and marking on the board surface.

Special Technology: The IMS PCB is equipped with High Thermal Conductivity technology, making it a standout choice for applications that require efficient heat dissipation and thermal management. This specialized feature ensures that the PCB can effectively transfer and dissipate heat, making it suitable for high-power and high-temperature applications.

PCB Thickness: The IMS PCB is available in a range of thicknesses, from 0.6mm to 6.0mm, providing flexibility and options to meet specific design requirements and performance needs.

Surface Finish: The IMS PCB offers a variety of surface finish options, including HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), Immersion Silver, and Immersion Tin. These surface finishes enhance the performance, reliability, and solderability of the PCB, catering to different application requirements.

Surface Finishing: The IMS PCB features a Plated Ni/Au surface finishing, which provides excellent conductivity, corrosion resistance, and solderability. This surface finishing ensures reliable performance and durability, making the PCB suitable for demanding applications.

The IMS PCB stands out as a high thermal conductivity metal PCB that delivers superior heat dissipation capabilities, making it an excellent choice for applications that require efficient thermal management. With its Begquist metal core PCB technology, the IMS PCB offers enhanced thermal conductivity and heat transfer properties, ensuring optimal performance in high-power and high-temperature environments.

Additionally, the IMS PCB utilizes Ventec metal PCB materials, known for their high-quality construction and reliability. The Ventec metal PCB technology enhances the thermal performance of the IMS PCB, making it a preferred solution for applications where heat dissipation is critical.

In conclusion, the IMS PCB is a versatile and reliable printed circuit board solution that combines advanced technology, high thermal conductivity, and superior performance. With its range of features and options, including silkscreen choices, special thermal management technology, varied thicknesses, surface finish options, and plated Ni/Au finishing, the IMS PCB is well-suited for a wide range of industries and applications that demand efficient heat dissipation and reliable performance.

Features:

-

Product Name: IMS PCB

-

Materials: Ventec, Polytronics, Bergquist

-

Surface Finishing: Plated Ni/Au

-

Tensile Strength: Excellent

-

Silkscreen Color: White, Black, Yellow

-

PCB Thickness: 0.6-6.0MM

Technical Parameters:

|

Withstand Voltage

|

>3KV

|

|

Number Of Layers

|

12-Layer

|

|

Silkscreen

|

White, Black, Yellow

|

|

Pcb Thickness

|

0.6-6.0MM

|

|

Min. Hole Size

|

0.2mm

|

|

Materials

|

Ventec, Polytronics, Begquist

|

|

Surface Finishing

|

Plated Ni/Au

|

|

Color

|

Green

|

|

Board Thickness

|

0.2-6.0mm

|

|

Min. Silkscreen Bridge

|

0.1mm

|

Applications:

IMS PCB, also known as Insulated Metal Substrate PCB, is a specialized type of printed circuit board that is designed for applications requiring high thermal conductivity and heat dissipation. The IMS PCB product is ideal for various occasions and scenarios due to its unique attributes:

Surface Finish:

The IMS PCB product offers a variety of surface finish options including HASL, ENIG, OSP, Immersion Silver, and Immersion Tin. These surface finishes provide excellent solderability and corrosion resistance, making the IMS PCB suitable for both industrial and consumer electronics applications.

Materials:

IMS PCBs are available in different materials such as Ventec, Polytronics, and Bergquist. Ventec metal PCB, PTTC metal PCB, and Ventec PCB are specifically designed for applications requiring high thermal conductivity and superior heat dissipation. These materials ensure reliable performance in high-temperature environments.

Special Technology:

The IMS PCB product features High Thermal Conductivity PCB technology, which allows for efficient heat transfer and thermal management. This special technology makes the IMS PCB ideal for power electronics, LED lighting, automotive, and aerospace applications where heat dissipation is critical.

Surface Finishing:

The IMS PCB product is finished with Plated Ni/Au, which provides excellent conductivity and solderability. This surface finishing ensures reliable electrical connections and minimizes signal loss in high-frequency applications.

Min. Hole Size:

The IMS PCB product has a minimum hole size of 0.2mm, allowing for precise component placement and routing. This feature is essential for applications requiring high-density interconnections and miniaturization.

Overall, the IMS PCB product is suitable for a wide range of applications and scenarios, including but not limited to power supplies, LED lighting, motor controls, automotive electronics, and telecommunications. Its unique attributes make it an ideal choice for demanding environments where thermal management and reliability are paramount.

Customization:

Product Customization Services for the IMS PCB product:

- Silkscreen: White, Black, Yellow

- Min. Silkscreen Bridge: 0.1mm

- Number Of Layers: 12-Layer

- Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin

- Board Thickness: 0.2-6.0mm

Support and Services:

Our Product Technical Support and Services for the IMS PCB product include:

- Troubleshooting assistance for any issues related to the IMS PCB

- Guidance on installation, setup, and configuration of the IMS PCB

- Software updates and patches to ensure optimal performance

- Training resources and materials for users and technicians

- Warranty support and repair services for defective IMS PCB units

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!