Product Description:

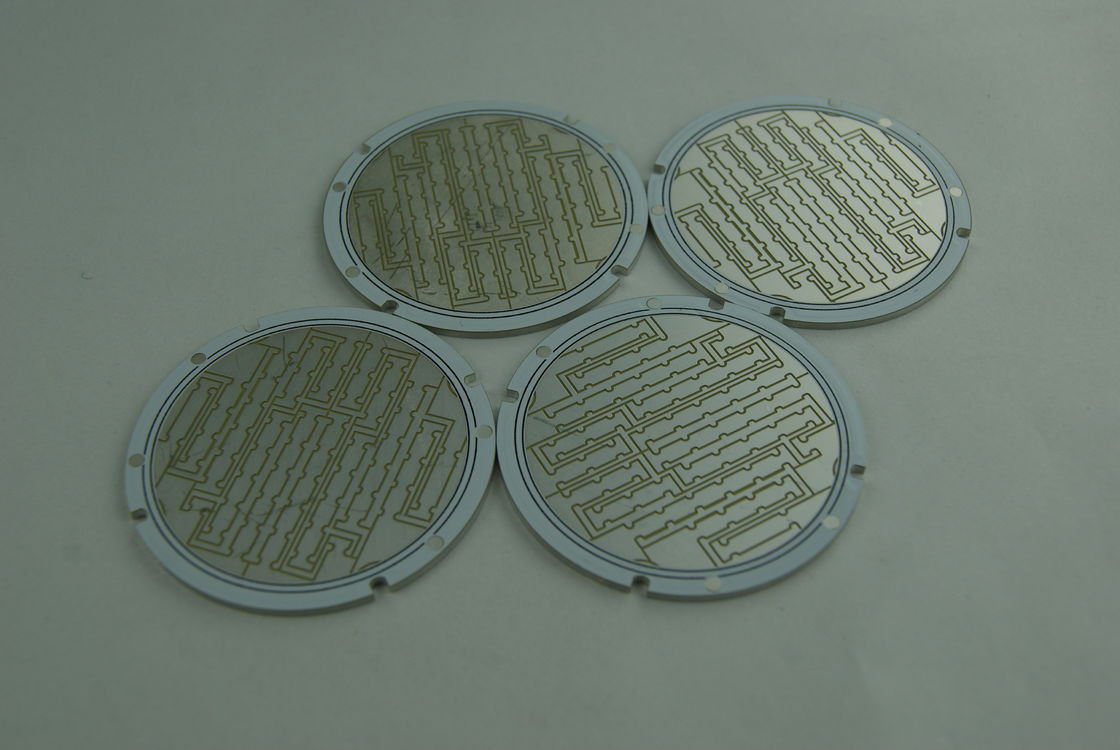

The IMS PCB, also known as Insulated Metal Substrate Printed Circuit Boards, represents a pinnacle of innovation in the PCB industry, particularly for applications requiring enhanced thermal dissipation. Our IMS PCB product is designed to meet the highest standards of quality and performance, making it an ideal solution for high-power and LED applications. This PCB is fabricated using Ventec PCB materials, known for their reliability and superior thermal management properties.

One of the critical features of our IMS PCB is the exceptionally fine Min. Line Width/Spacing, which stands at 0.075/0.075mm. This attribute allows for high-density circuit designs without compromising the integrity and performance of the PCB. Such precision in line width and spacing is instrumental for today's compact and complex electronic assemblies, providing our customers with the flexibility to design intricate circuits suitable for advanced technologies.

The silkscreen process for our IMS PCB is available in White, Black, and Yellow, offering a variety of choices to meet the aesthetic and functional requirements of our clients. The silkscreen is not only crucial for labeling and providing a guide for board assembly, but it also adds a layer of protection against external elements. It is meticulously applied to ensure legibility and durability, further enhancing the PCB's overall quality.

With a PCB thickness range of 0.6-6.0MM, our IMS PCB is versatile enough to be used in a wide array of applications. The varying thickness levels cater to different current-carrying capacities and mechanical strength requirements, which are paramount considerations for any electronic component. The robust design of our IMS PCB ensures that it can withstand the physical stresses of assembly and use, making it a reliable foundation for your electronic projects.

Understanding the importance of prototyping and testing, we offer samples of our IMS PCB. These samples are available to our customers to ensure that the product meets their specific needs before committing to a full production run. This service is invaluable for design validation, functionality testing, and overall confidence in the product's capabilities. By providing samples, we demonstrate our commitment to customer satisfaction and product excellence.

Our IMS PCB is engineered to endure high electrical stress with a withstand voltage of >3KV. This high voltage threshold is indicative of the PCB's robustness and reliability in challenging electrical environments. It makes our IMS PCB an excellent choice for power converters, automotive applications, and other devices that experience significant electrical loads. The capacity to maintain operational integrity at such high voltages is a testament to the meticulous design and manufacturing processes that go into every one of our IMS PCBs.

Lastly, the PTTC metal PCB aspect of our product refers to the metal core or base that provides outstanding thermal conductivity, leading to efficient heat dissipation. This metal core is a critical component for managing the thermal performance of the PCB, ensuring that heat generated by the electronic components is quickly and effectively transferred away from critical areas. This capability is particularly crucial in preventing overheating and improving the longevity of the electronic device.

Overall, our IMS PCB product stands out in the market for its precision, reliability, and thermal efficiency. Utilizing Ventec PCB materials and incorporating PTTC metal PCB technology, we are proud to offer a product that meets the evolving needs of the electronics industry. Whether for high-power applications, LED lighting solutions, or any other scenario requiring superior thermal management and electrical performance, our IMS PCB is a solution you can count on.

Features:

- Product Name: IMS PCB

- High Thermal Conductivity

- Withstand Voltage: >3KV

- PCB Thickness: 0.6-6.0MM

- Surface Finishing: CUSTOM

- Solder Mask Color: Clients Required

- Copper Thickness: 0.5-6.0oz

- Brand: Ventec PCB

- Material: Ventec Metal PCB

Technical Parameters:

| Attribute |

Details |

| Copper Thickness |

0.5-6.0oz |

| Withstand Voltage |

>3KV |

| PCB Thickness |

0.6-6.0MM |

| Sample |

Available |

| Number Of Layers |

1 Layer Printed Circuit Board |

| Thermal Conductivity |

0.5/1/2/3/5/8 W, 1.0w, >=1.0W/mK |

| Service |

Pcb Fabrication |

| Materials |

Ventec, Polytronics, Bergquist |

| Silkscreen |

White, Black, Yellow |

| Surface Finish |

HASL, ENIG, OSP, Immersion Silver |

Applications:

The IMS PCB, also known as Insulated Metal Substrate PCB, is a specialized product suitable for a wide array of applications where thermal management is crucial. The solder mask color for these PCBs can be tailored to the client's requirements, ensuring the final product matches the aesthetic needs of the application. With thermal conductivity options ranging from 0.5 to 8 W/mK, including specific values like 1.0w and >=1.0W/mK, IMS PCBs from Polytronics PCBs cater to various heat dissipation needs.

When it comes to power electronics, ventec pcb is well-known for their high performance, and the IMS PCBs are no exception. With copper thickness options from 0.5 to 6.0oz, they can handle significant current loads, making them ideal for applications such as LED lighting, automotive systems, and industrial power equipment. The robust structure of the PCB ensures that it can withstand voltages of >3KV, which is essential for safety and reliability in high-voltage circuits.

Furthermore, the precision of these PCBs is highlighted by their capability to maintain a min. line width/spacing of 0.075/0.075mm. This attribute is particularly important in dense circuit designs where space is at a premium, and signal integrity must be preserved. The fine line capabilities make the IMS PCBs perfect for use in advanced electronics where complexity and miniaturization are key, such as in aerospace or medical device technologies.

PTTC metal pcb products, including the IMS PCBs, are designed for scenarios where thermal performance and electrical insulation are paramount. They are suitable for use in high-power devices, renewable energy systems like solar inverters, and consumer appliances that require efficient heat dissipation. The robust design and superior thermal properties ensure that these PCBs can operate reliably in harsh environments, thereby extending the lifespan of the end product. Whether for industrial controls, power supplies, or rugged computing devices, the IMS PCBs provide a foundation for innovative and enduring electronic solutions.

Customization:

At our company, we offer comprehensive Product Customization Services for High thermal conductivity IMS (Insulated Metal Substrate) PCBs to meet the specific needs of our clients. Our customization options include a variety of features to ensure the highest performance for your PTTC metal pcb and ventec metal pcb requirements.

Our IMS PCB product boasts an impressive Withstand voltage of >3KV, ensuring reliability and safety for high voltage applications. The construction of this product is a 1 Layer Printed Circuit Board, tailored to provide efficient thermal management and space-saving benefits.

We provide a selection of Surface Finishes to choose from, including HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), and Immersion Silver. This variety allows us to cater to different industry standards and client preferences for surface protection and solderability.

Our customization service extends to the Type of the IMS PCB, where clients can select between an Insulation Sheet or a PCB Base Board, depending on the application's thermal and mechanical requirements. This flexibility ensures that our product can be integrated seamlessly into various types of electronic assemblies.

Additionally, we recognize the importance of aesthetics and brand identity in our products. Therefore, we offer Solder Mask Color customization according to Clients Required specifications. Whether you need a specific color to match your company branding or to distinguish different board functions, we have you covered.

Choose our Product Customization Services for a High thermal conductivity IMS PCB that meets all your PTTC metal pcb and ventec metal pcb requirements, with the assurance of quality, performance, and customer satisfaction.

Support and Services:

The IMS PCB product is supported by a comprehensive technical support and services package designed to provide you with the assistance you need to maximize the performance and longevity of your product. Our support services include a range of options to suit your specific requirements:

Product Documentation: Detailed user manuals, installation guides, and specification sheets are available to ensure you have all the information needed to effectively operate your IMS PCB.

Technical Support: Our team of experienced technical support engineers is available to help troubleshoot issues and provide solutions to any problems you may encounter with your IMS PCB.

Training Services: We offer training sessions to help your team get familiar with the product, understand its capabilities, and learn how to maintain it effectively to ensure optimal performance.

Firmware Updates: We regularly release firmware updates for the IMS PCB to enhance functionality, add new features, and address any known issues.

Repair Services: In the event that your IMS PCB requires repair, we offer a repair service to restore your product to its full functionality with minimal downtime.

Replacement Parts: We provide a full range of replacement parts to support the maintenance and repair of your IMS PCB, ensuring a long operational life and reducing the risk of extended downtimes.

On-Site Assistance: For complex issues or special requirements, our technical support team can provide on-site assistance to resolve any challenges directly at your location.

Our goal is to provide you with exceptional support and services to ensure that your IMS PCB operates efficiently and reliably. We are committed to the highest standards of customer satisfaction and product excellence.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!