Product Description:

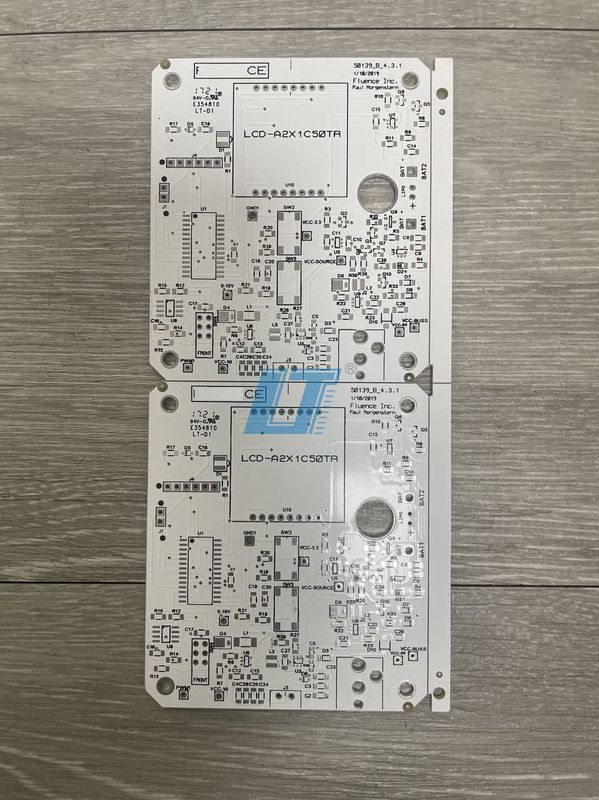

The IMS PCB, or Insulated Metal Substrate Printed Circuit Board, is a highly reliable and robust product designed to cater to the needs of advanced electronic applications that require superior thermal management. As industries continue to push the limits of electronic device performance, the choice of PCB material becomes increasingly critical. The IMS PCB stands out as a high thermal conductivity metal PCB, engineered to provide exceptional heat dissipation for high-power and high-temperature operations.

One of the most crucial attributes of this IMS PCB product is its ability to withstand high voltages. With a withstand voltage of greater than 3KV, this PCB is well-suited for applications that are exposed to high voltage conditions, ensuring safety and reliability under such demanding circumstances. The capacity to handle such high voltages makes the IMS PCB an ideal choice for power converters, automotive electronics, LED lighting solutions, and other applications that require robust performance.

Our IMS PCBs are available in a range of thicknesses, from 0.6MM to a substantial 6.0MM, catering to a variety of design specifications and mechanical stability requirements. This range of thickness options provides designers with the flexibility to optimize their circuit board for specific applications, whether it's for a compact consumer electronic device or a heavy-duty industrial component. The thickness of the PCB plays a pivotal role in the mechanical support of the mounted components as well as in the thermal management of the system.

The surface finishing of our IMS PCBs is customized according to client requirements. We understand that the surface finish can significantly affect solderability, corrosion resistance, and the overall longevity of the PCB. Therefore, we offer a selection of custom surface finishes to ensure that the final product perfectly aligns with the performance and durability expectations set by our customers.

Our commitment to quality is underscored by our adherence to international standards, as demonstrated by our ISO certifications. We are proud to be certified under ISO 9001:2015 for quality management systems, ISO 14001:2015 for environmental management systems, and ISO 13485:2016 for medical devices quality management. These certifications are a testament to our dedication to providing high-quality products while maintaining environmental responsibility and ensuring the production of safe and effective medical devices.

As a PTTC metal PCB, the IMS PCB product benefits from Polytronics' advanced Thermal Conductive Technology, which greatly enhances the PCB's ability to transfer heat away from critical components, thereby increasing the longevity and reliability of the devices it powers. Polytronics PCBs are known for their superior thermal performance, and this product is no exception. It is designed to manage the thermal challenges of modern electronics, ensuring that heat is effectively dissipated to prevent overheating and maintain optimal performance.

Our service extends beyond just providing a high-quality PCB; we offer comprehensive PCB fabrication services. This means that from the moment you share your design requirements with us, we take care of the entire manufacturing process, ensuring that the final product is fabricated to the highest standards. Our state-of-the-art fabrication facilities are equipped with the latest technology and are operated by skilled technicians who are committed to delivering excellence in every PCB that we produce. With our expertise in PCB fabrication, customers can expect a seamless and efficient process, resulting in a product that meets their exacting standards.

In summary, the IMS PCB product is an exceptional solution for those seeking a high thermal conductivity metal PCB capable of operating under high voltage conditions and within a range of thicknesses. With custom surface finishing options, rigorous ISO certifications, and our unparalleled PCB fabrication service, we provide our customers with a product that is not only reliable and robust but also tailored to meet their specific needs. Whether for industrial, automotive, medical, or consumer electronics, the IMS PCB is the substrate of choice for designers and engineers who demand the best in thermal management and electrical performance.

Features:

- Product Name: IMS PCB - PTTC metal pcb

- Min. Line Width/Spacing: 0.075/0.075mm

- Withstand voltage: >3KV

- PCB thickness: 0.6-6.0MM

- Service: PCB Fabrication - Polytronics PCBs

- Surface Finish: HASL, ENIG, OSP, Immersion Silver - ventec metal pcb

Technical Parameters:

| Technical Parameter |

Specification |

| Solder Mask Color |

Clients Required |

| Silkscreen |

White, Black, Yellow |

| Surface Finishing |

CUSTOM |

| Copper Thickness |

0.5-6.0oz |

| ISO Certification |

ISO 9001:2015, ISO 14001:2015, ISO 13485:2016 |

| Min. Line Width/Spacing |

0.075/0.075mm |

| Surface Finish |

HASL, ENIG, OSP, Immersion Silver |

| Thermal Conductivity |

0.5/1/2/3/5/8 W/mK, 1.0w, >=1.0W/mK |

| Number Of Layers |

1 Layer Printed Circuit Board |

| Type |

Insulation Sheet, PCB Base Board |

Applications:

IMS PCBs, also known as Insulated Metal Substrate Printed Circuit Boards, are engineered to cater to applications that require higher thermal dissipation. With a minimum line width/spacing of 0.075/0.075mm, they are designed for precision and high-density integration. The product's thermal conductivity ranges from 0.5 to 8 W/mK, inclusive of specific grades like 1.0W and >=1.0W/mK, ensuring efficient heat management across various use cases.

Constructed from quality materials provided by industry leaders such as Ventec, Polytronics, and Bergquist, IMS PCBs assure reliability and performance. Ventec PCBs are known for their robust build and thermal efficiency, making them ideal for demanding environments. Similarly, Polytronics PCBs stand out for their excellent thermal management capabilities, catering to applications where heat dissipation is critical. The availability of various surface finishes such as HASL, ENIG, OSP, and Immersion Silver allows for flexibility in application and ensures good solderability and protection against oxidation.

The copper thickness of IMS PCBs ranges from 0.5 to 6.0oz, accommodating different current-carrying requirements and enhancing the thermal spreading properties. This makes IMS PCBs especially suited for power converters, LED lighting solutions, automotive systems, and high-power circuits where thermal management is crucial. For example, in LED applications, a ventec metal pcb can efficiently channel heat away from the LEDs, significantly improving their lifespan and performance.

Application occasions for IMS PCBs span across various industries, from automotive electronics where the emphasis is on reliability and longevity, to consumer electronics where sleek design and effective cooling are paramount. They are also frequently utilized in industrial power equipment, renewable energy systems, and high-speed computing where managing heat is essential for system stability and performance.

In scenarios where electronic devices are exposed to harsh environments, the robustness of a Polytronics PCB ensures durability and consistent performance. Whether it's in outdoor communication equipment or high-grade military hardware, the combination of Polytronics' thermal expertise and IMS PCB design offers an unmatched solution.

Overall, the IMS PCB product, with its specific attributes of fine line precision, superior thermal conductivity, a range of surface finishes, and varying copper thicknesses, is a versatile solution that meets the high standards of numerous applications and scenarios, be it in a ventec pcb or a ventec metal pcb configuration.

Customization:

We offer premium Product Customization Services for our IMS PCB product range, tailored to meet your specific requirements. Our Ventec metal PCBs are designed with precision, featuring a Min. Line Width/Spacing of 0.075/0.075mm for fine detail work. They are engineered to Withstand voltages of over 3KV, ensuring reliability and safety in high-voltage applications.

Samples of our PTTC metal pcb are Available upon request, allowing you to verify the quality and compatibility with your designs before mass production. We provide a variety of Surface Finishes, including HASL, ENIG, OSP, and Immersion Silver, to cater to different assembly requirements and enhance the longevity of your PCB.

Our High thermal conductivity metal pcb options range from 0.5/1/2/3/5/8 W/mK to 1.0W/mK and >=1.0W/mK, accommodating various heat dissipation needs for your electronic components. This adaptability ensures optimal performance and reliability of your devices in various operating conditions.

Support and Services:

The IMS PCB product comes with comprehensive technical support and services to ensure maximum satisfaction and performance. Our support team is dedicated to providing prompt and accurate assistance to address any technical issues you may encounter with your IMS PCB. We offer a range of services, including:

- Technical Troubleshooting: Our experts are available to help diagnose and resolve any technical problems you may encounter during the installation or use of your IMS PCB.

- Product Documentation: Access detailed documentation for your IMS PCB, including user manuals, installation guides, and specifications, to support your understanding and use of the product.

- Firmware and Software Updates: Keep your IMS PCB up to date with the latest firmware and software enhancements to ensure optimal performance and access to new features.

- Best Practice Advice: Receive advice on best practices for using and maintaining your IMS PCB to ensure longevity and reliability of the product.

- Repair Services: In the unlikely event that your IMS PCB requires repair, we can provide you with information on how to access our repair services to get your product back to optimal condition as quickly as possible.

Our goal is to provide you with the support you need to fully benefit from the capabilities of your IMS PCB. We are committed to delivering quality technical support and services to enhance your experience with our product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!