Product Description:

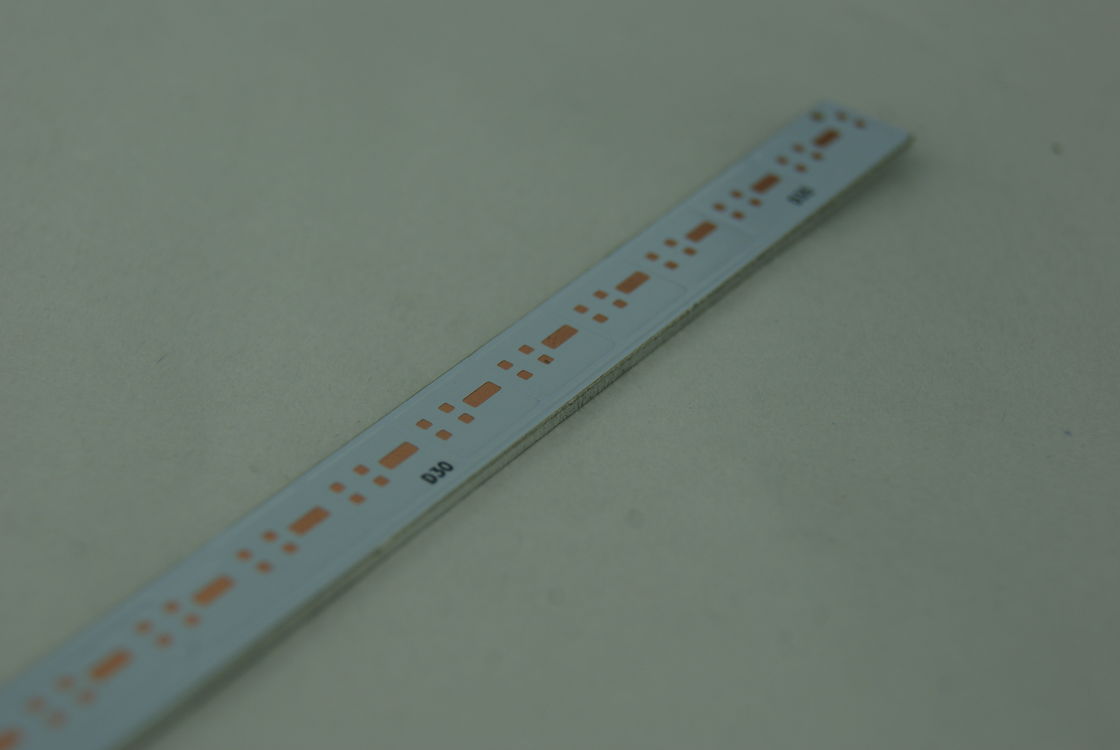

The IMS PCB (Insulated Metal Substrate Printed Circuit Board) is a revolutionary product in the electronics industry designed to provide a robust platform for a wide range of applications, especially in power electronics where thermal management is a critical factor. This product is crafted using high-quality materials from industry-leading suppliers including Ventec, Polytronics, and Bergquist, ensuring a reliable foundation for your electronic components.

Our IMS PCBs are constructed with materials known for their excellent thermal properties. Ventec materials are well-regarded for their dependable performance and consistent quality. Polytronics PCBs are synonymous with innovation, providing high thermal conductivity metal PCBs that are both durable and effective in dissipating heat. Lastly, Bergquist metal core PCBs are included in our material lineup for clients who demand superior thermal management and reliability in their applications.

The copper thickness available for our IMS PCB products ranges from 0.5oz to 6.0oz. This wide range allows for a high degree of customization based on current carrying requirements and thermal dissipation needs. Whether you are designing a circuit that requires minimal copper for lightweight applications or a robust circuit that necessitates a thicker copper layer to handle higher currents, our IMS PCB can be tailored to your specifications.

When it comes to surface finish, our IMS PCBs offer a variety of options to meet the diverse needs of our customers. HASL (Hot Air Solder Leveling) is a popular choice for its cost-effectiveness and good solderability. ENIG (Electroless Nickel Immersion Gold) provides a flat surface and excellent corrosion resistance, making it suitable for fine-pitch components. OSP (Organic Solderability Preservatives) is an environmentally friendly option that provides a clean surface for soldering without the use of lead or other heavy metals. Immersion Silver is another available finish which offers good thermal fatigue resistance and is also suitable for fine-pitch components.

Custom surface finishing is another feature that sets our IMS PCB products apart. Clients can specify their surface finish requirements, ensuring that the final product meets their unique needs, whether it is to enhance solderability, increase lifespan, or ensure compatibility with specific components. This level of customization is part of our commitment to providing versatile and effective solutions for our clients’ diverse applications.

The types of IMS PCBs we offer include Insulation Sheets and PCB Base Boards. Insulation Sheets are essential for managing heat and maintaining electrical isolation between components. Our PCB Base Boards serve as the structural foundation for mounting and interconnecting the electronic components. Both types are designed to operate efficiently under thermal stress and provide a reliable base for your electronic systems.

With high thermal conductivity metal PCBs, our IMS PCB products excel at dissipating heat, which is critical for maintaining the performance and longevity of electronic components. This high thermal conductivity is particularly important in high-power devices where overheating can lead to failure or reduced efficiency. Our IMS PCBs are designed to handle these thermal challenges, ensuring your devices operate within safe temperature ranges for extended periods.

In summary, the IMS PCB product from our range offers a comprehensive solution for those in need of high-performance, thermally efficient circuit boards. By combining the strengths of materials from Ventec, Polytronics, and Bergquist with a wide range of customization options in copper thickness and surface finishes, we ensure that our clients receive a product that not only meets but exceeds their expectations in terms of quality, reliability, and performance.

Features:

- Product Name: IMS PCB

- Copper Thickness: 0.5-6.0oz

- Thermal Conductivity: 0.5/1/2/3/5/8 W/mK

- Service: PCB Fabrication

- Materials: Ventec, Polytronics, Bergquist

- Type: Insulation Sheet, PCB Base Board

- PTTC Metal PCB: IMS PCB with PTTC (Plated Through Thermal Conductivity)

- High Thermal Conductivity IMS PCB: Ensures efficient heat dissipation for high-power applications

Technical Parameters:

| Technical Parameter |

Specification |

| PCB Thickness |

0.6-6.0MM |

| Service |

Pcb Fabrication |

| Number Of Layers |

1 Layer Printed Circuit Board |

| Type |

Insulation Sheet, PCB Base Board |

| Solder Mask Color |

Clients Required |

| Min. Line Width/Spacing |

0.075/0.075mm |

| Materials |

Ventec, Polytronics, Bergquist |

| ISO Certification |

ISO 9001:2015, ISO 14001:2015, ISO 13485:2016 |

| Sample |

Available |

| Copper Thickness |

0.5-6.0oz |

Applications:

The IMS (Insulated Metal Substrate) PCB, with its remarkable product attributes, is suitable for a multitude of application occasions and scenarios. IMS PCBs are designed to cater to high-performance electronic products that require effective thermal management. With thermal conductivity options ranging from 0.5 W/mK to an impressive 8 W/mK, these PCBs are perfect for heat dissipation in power converters, LED lighting systems, automotive electronics, and high-power machinery.

When it comes to surface finish, the IMS PCB product offers a variety including HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), and Immersion Silver. Each of these finishes ensures excellent solderability and reliability, making the IMS PCB suitable for high-density component mounting found in sophisticated electronic devices and telecommunications equipment. For instance, the ENIG finish is ideal for complex, fine-pitch components, while HASL is commonly used for general applications.

The IMS PCB comes in a 1 Layer Printed Circuit Board configuration, which is optimal for applications where space and weight are at a premium, such as in mobile devices and wearable technology. The high withstand voltage of over 3KV also makes these PCBs ideal for power supply units and industrial controls where electrical safety is critical.

With a choice of silkscreen colors—white, black, and yellow—designers have the flexibility to optimize the contrast and visibility of markings on the PCB, which is particularly useful in assembly lines and during maintenance checks. The clarity provided by the appropriate silkscreen color can be critical in avoiding assembly errors and ensuring operational efficiency.

Brands like Begquist metal Core pcb, Polytronics PCBs, and ventec metal pcb are known for their quality IMS PCB products. They are industry leaders in providing PCBs that meet the stringent requirements of modern electronics. Whether it's for high-intensity LED applications or power regulators, these brands offer IMS PCBs that ensure durability, high thermal performance, and electrical insulation tailored to specifically address the needs of specialized electronic components.

In summary, the IMS PCB product is a versatile solution that caters to a wide range of electronic devices, thanks to its impressive thermal conductivity, robust withstand voltage, and variety in surface finishes and silkscreen options. It's the go-to choice for manufacturers who need a reliable, single-layer PCB for their heat-sensitive applications.

Customization:

Thermal Conductivity: High thermal conductivity IMS PCB options available with 0.5/1/2/3/5/8 W/mK, including specialized options with 1.0w and >=1.0W/mK to suit your specific heat dissipation requirements.

Number Of Layers: Our product line includes 1 Layer Printed Circuit Board, expertly designed for efficient performance.

ISO Certification: Quality and environmental management systems that are ISO 9001:2015, ISO 14001:2015, and ISO 13485:2016 certified, ensuring our IMS PCBs meet the highest industry standards.

Surface Finishing: We offer CUSTOM surface finishing for enhanced performance and reliability of your ventec metal pcb.

Solder Mask Color: The solder mask color can be tailored to Clients Required specifications, providing a personalized touch to your Begquist metal Core pcb.

Support and Services:

The IMS PCB product comes with comprehensive technical support and services designed to provide you with the necessary assistance for optimizing the performance and extending the life of your printed circuit boards. Our support package includes the following:

Product Documentation: We offer a complete set of detailed documentation that includes installation guides, user manuals, and maintenance instructions to help you understand and operate your IMS PCB effectively.

Troubleshooting Assistance: Our skilled technicians are available to help diagnose and solve any issues you may encounter with your IMS PCB. This service aims to minimize downtime and ensure your operations continue smoothly.

Firmware Updates: We provide regular firmware updates that enhance the functionality of your IMS PCB, fix known bugs, and add new features to keep your product up-to-date.

Technical Training: To ensure that you and your team can fully leverage the capabilities of the IMS PCB, we offer technical training sessions that cover various aspects of the product's operation and maintenance.

Replacement Parts: In the event that any component of your IMS PCB requires replacement, we supply genuine replacement parts to maintain the quality and performance of your product.

Preventive Maintenance: Our preventive maintenance services are designed to identify and address potential issues before they become problems, thus prolonging the life of your IMS PCB.

Warranty Support: The IMS PCB comes with a standard warranty that covers defects in materials and workmanship. We stand behind our product and will provide the necessary support to resolve any warranty-related concerns.

Please note that some of the above services may require additional fees or may be included as part of an extended service package. For more information on the technical support and services available for the IMS PCB product, please refer to the specific terms and conditions outlined in your purchase agreement or contact our customer service team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!